FIMAC and One Team: digitalization in aerospace

FIMAC was founded more than a hundred years ago, with the creation of a pneumatic drill. In 1930 starts the production of a new series of aeronautical products applied to a fleet of hydroplanes, that later crosses the Atlantic . Starting from 1932, FIMAC supplies oil and gas pumps for Bristol Pegasus engines to Alfa Romeo.

In the 50s starts the production of propeller pitch regulators for Piaggio. The evolution progresses with time, with the participation to the Viper engine program and the production of BFCU, new pressure switches, and such. FIMAC wins international contests in the EFA for hydraulic accessories and the subalar pod thermal control for the Eurofighter.

Today, FIMAC is an independent player on the global market. FIMAC consolidated its position with patents and production of equipment for avionic cooling systems, acquiring different orders for systems for reconnaissance pods mounted on S aab JA S 39 Gripen, F16, and Sukoi SU 30 planes . FIMAC ’s product is sold worldwide, and the company manages its whole production process: design, process development, detail realization, testing, assembling, and sales .

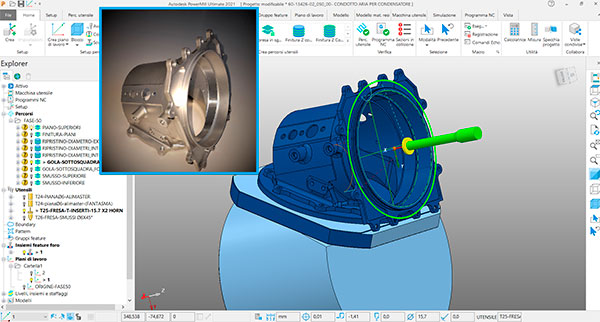

FIMAC is driven by two main objectives: the clients’ needs and the wish to constantly improve projects and solutions . In 2004 the CAD/C AM ex periments begun: an empty warehouse, a five-ax is machine and the first Delcam’s Powermill software. There, the digitalization process started.

Autodesk bought Delcam and FIMAC started relying on One Team.

Now, with the use of Powermill, FeatureC AM and Powerinspect, FIMAC has a team of 14 people involved with the digital design of highly specialized products . The choice of C AD/C AM software for the mechanical processing of the machining centers is essential. Given FIMAC ’s needs – to obtain tools able to guarantee the highest precision for the design of a very delicate product with small units of measurement and to work on complex shapes made with solid billet and not moulds – the selection ended up being successful. Powermill and FeatureCAM allowed the team to develop perfect solutions, ex act in every detail, without much margin of error.

FIMAC established with their software partner One Team a direct relationship. The real advantage of this type of partnership is this to build a rapport of close collaboration to solve problems, reduce times, and exchange ideas. Developing this type of machine is complicated: the technology is fast and changes rapidly. Seeing their product evolve with their needs, is efficiency.