HITEMA®, Advanced Freecooling Solutions For HVAC Industry

Hitema® International is a specialist manufacturer of customized solutions for process cooling and industrial comfort applications. In this article we would like to explain the advantages of using our Chillers with Freecooling technology.

FREECOOLING TECHNOLOGY Process applications for cooling systems that have constant production loads and generate high process fluid temperatures (water 20/15 °C or higher) are particularly good candidates to take advantage of low ambient temperatures and therefore the functionality of Freecooling. Low ambient temperatures can be used as a “free” energy source, replacing the electricity needed to run the compressors, in what is known as a Freecooling or Freecooling system.

FREE COOLING METHODS:

Freecooling technology can be:

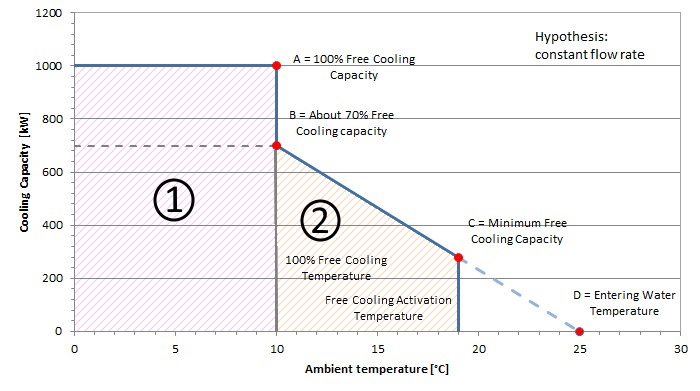

-TOTAL: The external air temperature allows to satisfy the entire refrigeration request. All the cooling capacity is therefore guaranteed by the only external air that passes through the Freecooling coils while the compressors remain off.

In this case, maximum energy savings are achieved.

-PARTIAL: When the external air temperature is lower than that of the return water, but not enough to obtain total Freecooling, there is a partial one. A part of the cooling capacity is supplied by the external air while the remainder by the compressors, thanks to the optimized management of resources, hybrid refrigeration is therefore achieved.

The Freecooling system developed by Hitema® International is in partial mode. This system allows to use the most of the low temperatures of the winter months and also offers significant advantages in terms of energy savings even in transition seasons such as autumn or spring. Integrated in a chiller system, the system automatically decides, based on the ambient temperature and the operating logic, whether to operate as a chiller or as a partial or total freecooler.

The Freecooling of the water can be carried out in all seasons of the year, both with the refrigeration compressors “ON” (Partial Freecooling) and with the compressors “OFF” (Total Freecooling).

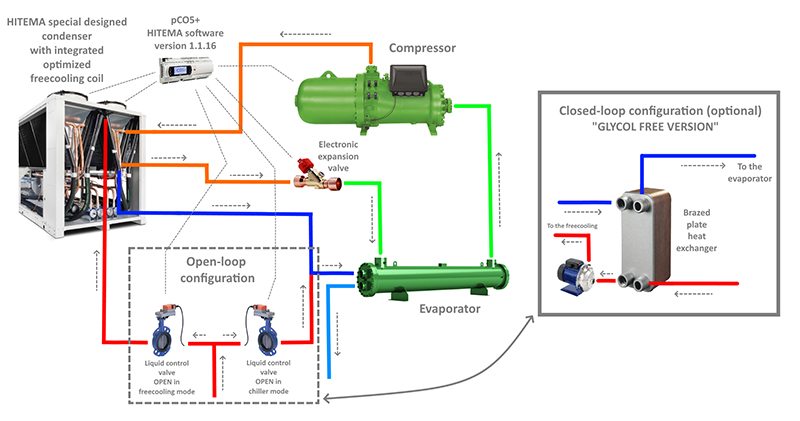

Freecooling in partial mode is made possible by the separation of the chiller and Freecooling systems, consequently the chiller and the Freecooling will have their respective fans.

In partial Freecooling mode, the system starts cooling when the ambient temperature is 3.6 / 4 °F below the fluid inlet temperature. The water is conveyed through a three-way valve first to the freecooler and then goes to the Chiller. The controller automatically reduces the work of the compressors by limiting the cooling capacity by controlling the 3-way valve (or two gate valve) (which controls where the incoming water goes).

During the transitional months of autumn and spring, Freecooling acts as a pre-cooler and significantly reduces the power absorbed by the compressors and consequently the energy consumption of the chiller.

In the case that the ambient temperature drops to extremely low levels, the 3-way valve (or the two gate valve in this case) modulates and bypasses part of the flow, mixing it with the fluid leaving the coil, always maintaining perfect control of the fluid temperature at the outlet.

CONCLUSION:

The use of Freecooling technology allows users to achieve a reliable payback time compared to traditional water Chillers. Depending on the weather conditions and the fluid temperatures, the return on investment is almost always close to the year. An innovation in Freecooling has been developed with the introduction of Freecooling in partial mode, allowing for a significantly wider range of application temperatures and significant energy savings.

For more information:

www.hitema.com

customer.care@hitema.it