Melos; a special compounder for all cases

Melos GmbH from Melle is a leading manufacturer of compounds for the cable industry and customized compounds for the plastics processing industry. In this small town in Lower Saxony, more than 50,000 tons of industrial compounds are produced annually in the Industrial Compounds division.

Insulating, bedding and sheathing compounds are developed especially for the cable industry, but also special formulations. The high-quality low-smoke, HFFR, thermoplastic and radiation-crosslinkable compounds, including halogenated specialties, are used worldwide in cables for a wide variety of applications.

Safety starts behind your own 4 walls – sometimes things heat up Cables for building installations are partly covered by the European Construction Products Regulation for public buildings, and not without reason.

•Flame retardant cables contain halogen-free flame- retardant bedding compounds with different degrees of flame protection (LOI 30-67 % O2), for example NHXMH power cables. This reduce the risk of fire in case of emergency.

•Migration-stable bedding compounds for PVC sheathing / PVC insulation / XLPE insulation and cable constructions protect the cables against mechanical stresses. •EPDM- and POE- based bedding compounds in different degrees of hardness and viscosity allow NYM & NYY underground cables to be installed quite flexibly.

Melos compounds are available for tandem- as well as for 2-step extrusion process.

Green Energy – Wind as a driver for the energy turnaround: The energy turnaround now demands quick solutions.

Alternative, sustainable solutions are particularly in demand at the present time. Offshore wind turbines as a source of energy are increasingly coming into focus.

In this context, the cables of offshore wind farms have to withstand extreme demands. Melos compounds deliver a lot of advantages:

•Halogen-free, highly flame-retardant sheathing materials prevent fire spread in the event of fire

•Low-smoke, halogen-free compounds reduce the acidity of fire gases

•Excellent cable flexibility even at extreme low temperatures down to -70°C

•Excellent resistance to oils and other media ensures continuous use of the cables used

•High UV & aging resistance prevents premature aging of the cables

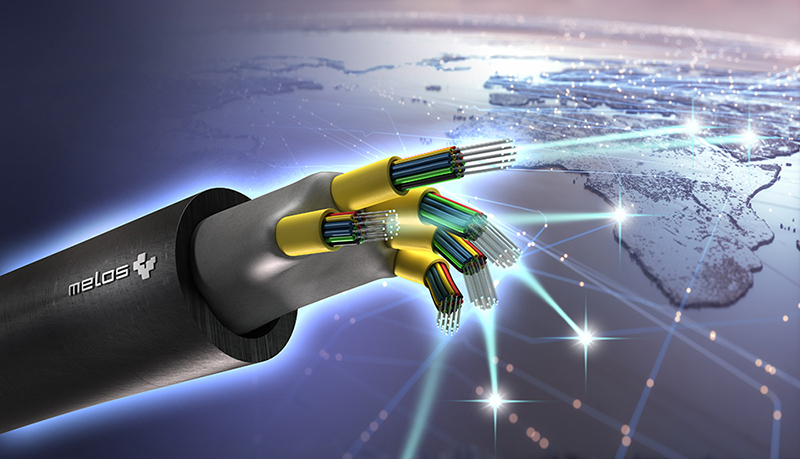

Fast and stable Internet

Home office, streaming, ever-increasing data volumes

– these are current challenges that also place special demands on fibre optic cables. In terms of structure and properties, these are not quite comparable with conventional cables.

Fibre optic cables must:

•allow thin-walled cable structures, for which HFFR

Tight Buffer materials are used

•must allow only slight shrinkage of the HFFR sheath materials to prevent damage to the sensitive glass fibres.

•be easy to process, e. g. with HFFR Tube materials with good melt stability as an alternative to polypropylene

•cover the fire behaviour with respect to the CPR Construction Products Regulation according to EN 50399, which can be achieved with HFFR filling compounds for loose tube applications

Melos compounds offer here an excellent solution for the production of fibre optic cables and thus a stable internet.

Want to learn more? Visit us at the Wire 2022 in Düsseldorf

For more information:

www.melos-gmbh.com

info@melos-gmbh.com