New material testing across the end-to-end Hydrogen value chain

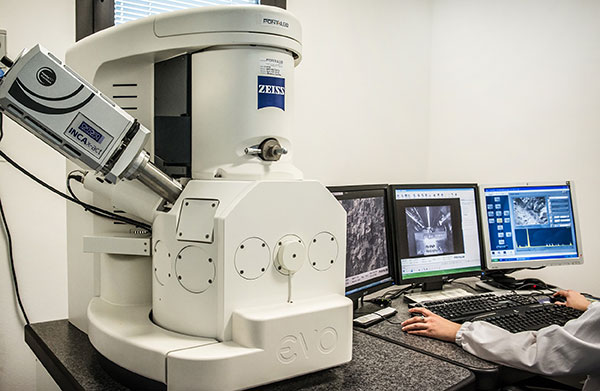

Pontlab is one of the main laboratories for material characterization and research located in Italy.

The Metallic Materials Department operates in Microstructural Analysis, Failure Analysis, Erosion, Corrosion and Stress Corrosion Testing both in low and High Temperature/Pressure. Pontlab provides test and analysis services to more than 300 industrial customers per year in different industrial sectors, such as steelmaking, automotive, energy, chemicals, aerospace.

Furthermore it operates in connection with universities and institutions, participating in several research projects.

Hydrogen is expected to play a key role as an energy carrier in future energy systems of the world, underpinned by a global shift of regulators, investors, and consumers toward decarbonization. The Hydrogen

Council estimates that if all existing H2 projects come to fruition, total investments will exceed USD 300 billion spending through 2030.

In this moment, the request of material characterization in H2 environment is rapidly growing. The main problem that all manufacturers of machines and components using hydrogen will have to face, will be the development and validation of specific materials.

Current state of the art in testing on materials in contact with hydrogen are limited to research activities carried out mostly in the university context and few upcoming laboratories in the world. From a strictly technical point of view, the most investigated problem is the so-called Hydrogen Embrittlement (HE) on metallic materials, which represents an insidious cause of material failure. Pontlab, thanks to its many years of experience, implemented in its laboratories during summer 2021 the ASTM G142 – 98(2016) “test method for determination of susceptibility of metals to embrittlement in hydrogen containing environments at high pressure”. The test method consists in exposing specimens of selected materials to a gaseous H2 containing environment at high pressure or high temperature, while being pulled to failure in uniaxial tension. The susceptibility to hydrogen embrittlement is evaluated through the determination of standard mechanical properties in tension in comparison to those determined in a non-embrittling environment (control test). The results from this test method can be used to evaluate the effects of material composition, processing, and heat treatment as well as the effects of changes in environment composition, temperature, and pressure.

More info about Pontlab tests:

www.pontlab.it | info@pontlab.it