Carlo Salvi SpA is a world-renowned designer and producer of heading machines for the production of screws, semi-tubular and fully tubular rivets, bolts, special fasteners and parts with very complex shapes starting from drawn wire in coils.

Machines can be divided in three main families, namely:

– single die double blow headers;

– 2-die 4-blow headers;

– progressive precision transfer headers.

The machines of the 2-die 4-blow series are able to handle wire diameters from 1,2 to 12 mm.

They are particularly suitable for components whose heads have a very large volume or components where two dies are sufficient but at least three blows are needed, such as for instance allen screws, trimmed components etc.

A great advantage of these machines is due to the fact that the third blow can very often be used as an introduction punch if parts with large heads and a very short shank have to be transferred.

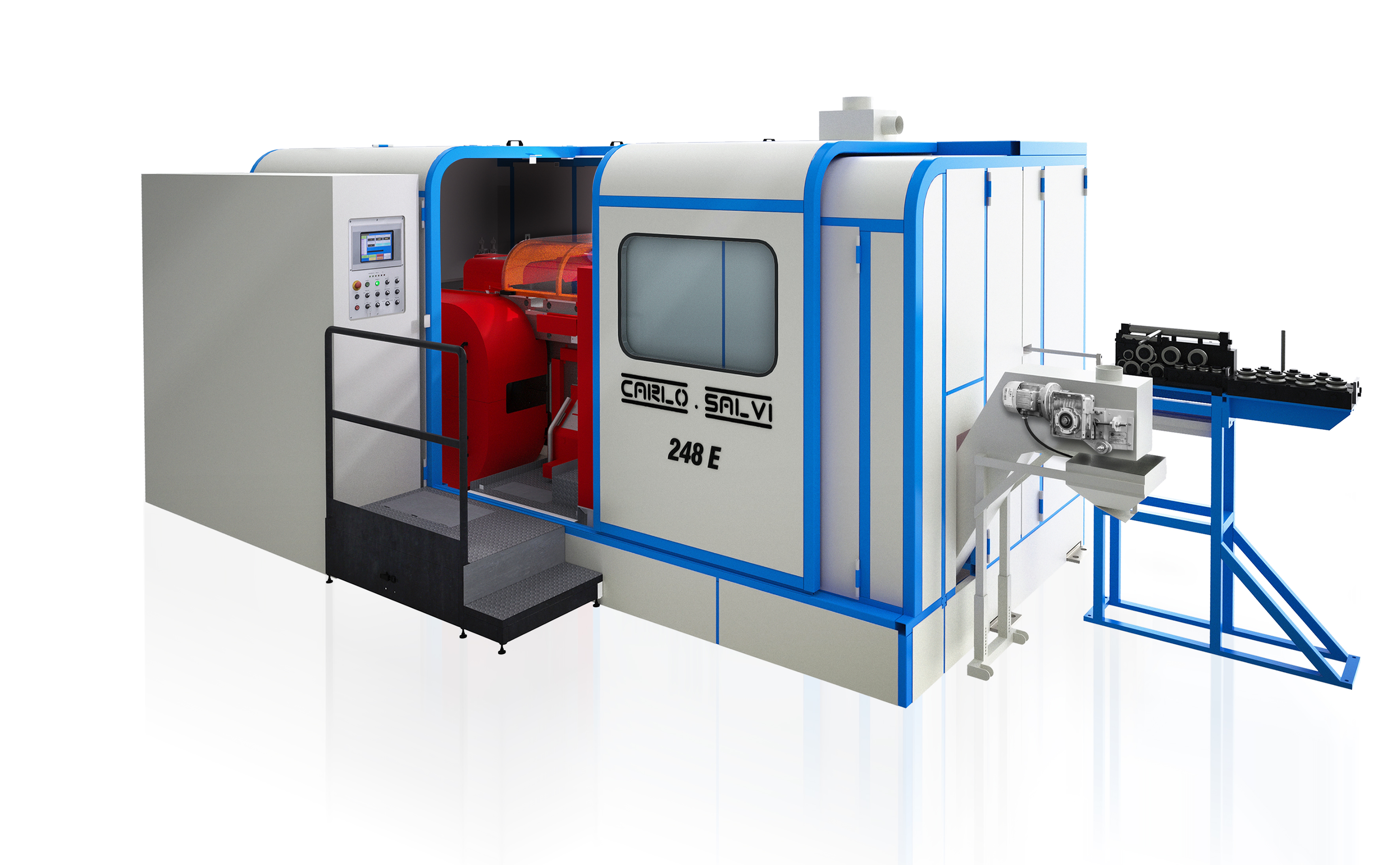

Carlo Salvi has developed a new motorized model which is called 248 E, which is an enhanced version of the model 248 machine. The machine is complete with an electro-pneumatic clutch which allows maximum heading tonnage to be applied even when jogging.

The machine has been specially developed in order to minimize changeover times. Its technology and speed is such that it enables to run profitably not only large volumes but also small batches.

An example of set‑up and changeover times follows:

– k.o. length adjustment first die 30 seconds

– k.o. length adjustment second die 30 seconds

– cutoff length adjustment 30 seconds

– adjustment of opening and closing cams 5 minutes

– assembly of dies 5 minutes

– assembly of punch block unit 5 minutes

– assembly of cutter unit 1 minute

– assembly of transfer fingers 1 minute

Technical data of the header model 248 E:

min and max wire diameter mm 4-12,5 mm (steel) 4-10 mm (titanium)

max shank length mm 82

max head diameter mm 20

max cutting tonnage daN 6500

max heading tonnage daN 55000

stroke of P.K.O.’s mm 20

Between the main standard features of this machine, we can list:

– linear wire feed, without rolls without wire-stop

– K.O. die side and punch side

– motorized lifting/lowering of transfer unit

– conveyor

– bad part divert

– transfer fingers

The header model 248 E can be enriched further with some optional items as, for examples, the quick change kit, which includes: punch block unit, transfer unit, cutter holder unit, cutter centring jig, punch centring jig, transfer centring jig.

To handle of material like titanium and super alloys, which can not be formed with the cold heading system, the header can be equipped with a pre-heating system.

The customer can decide to install on the header model 248 E the heating system with coil housed on the die holder, or the resin-bonded inductor positioned into the bedframe. In the event of special production needs, it is possible to evaluate also to install both kind of inductors.