MYWAITM: Pioneering Edge, Multimodal & Generative Artificial Intelligence for Smarter Manufacturing from Italy to the US

Intelligence as Never Before

During the Renaissance, the renowned Italian artist, painter, inventor, and scientist Leonardo da Vinci demonstrated how humanity could design smarter machines to enhance contemporary living and working conditions. Fast-forward to today, and MYWAITM, Italy’s fastest-growing industrial AI startup, is poised to revolutionize industries worldwide.

During the challenging years of 2021 and 2022, when Italy faced the brunt of the pandemic, MYWAITM emerged as a beacon of innovation. The startup established its Research Centre in the serene Silence Bay of Sestri Levante, nestled in the picturesque northwestern Italian Riviera and achieved an impressive $3 million turnover within just 24 months of inception delivering proof of value for leading European and Japanese manufacturers such as ESAOTETM (Biomedical), MITSUBISHI ELECTRICTM (Robotics/Industry 4.0), Hi-LexTM (Automotive), and HITACHI RAILTM (Transport).

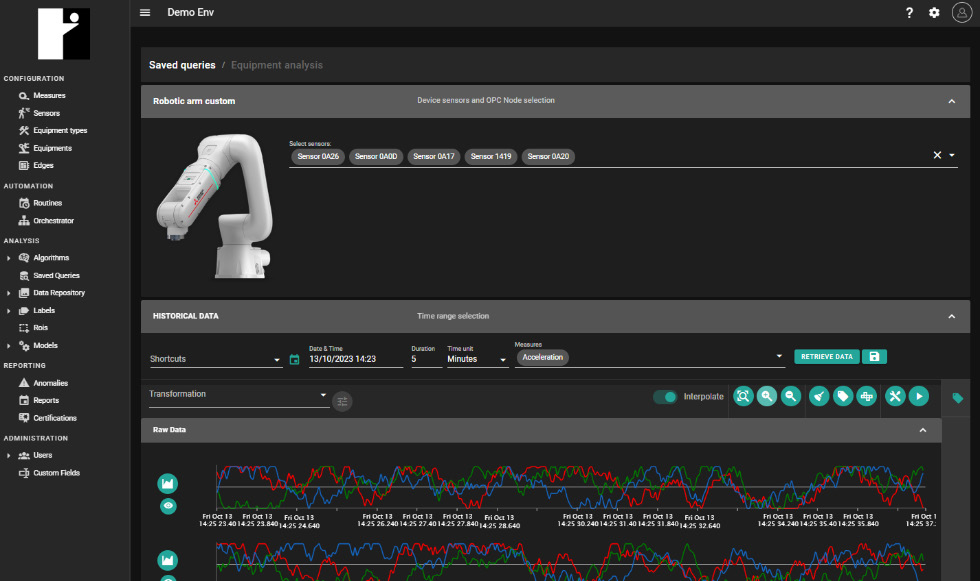

Robotics manufacturer Mitsubishi Electric™

Today MYWAITM is at the forefront of AI innovation, exploring exciting new directions that redefine the concept of smart equipment by adding to machinery:

1.Edge AI: MYWAITM harnesses the power of edge computing, enabling machines to process data locally, right where it’s generated. This approach ensures real-time decision-making and minimizes latency empowering machines that can adapt swiftly, even in challenging environments like factories, cities, and hospitals.

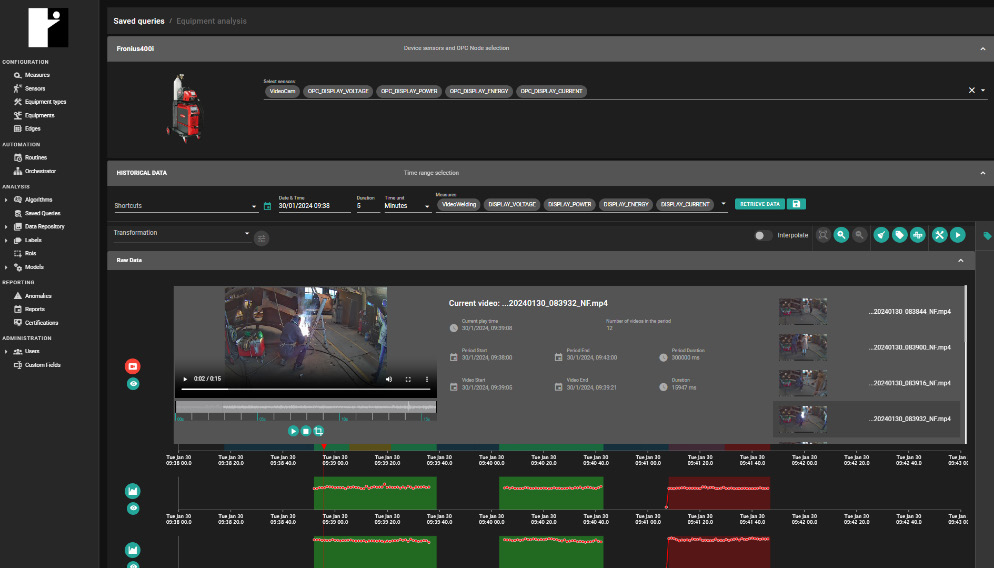

2.Multimodal AI: MYWAITM integrates various data modalities—text, images, and audio—into a cohesive framework.

By understanding and interpreting diverse inputs, their AI systems become more versatile and context aware.

3.Generative AI: Italian creativity meets industrial intelligence. MYWAITM explores generative models for new machinery that can create new content, whether generated defects, or synthetic product anomalies pushing the boundaries of AI usage in quality control.

Welding player San Giorgio SEIGEN™

4.Agentic AI: MYWAITM empowers machines with Reinforcement Learning and Intelligent Agents. These AI systems can take proactive steps, adapt to changing conditions, and even heal themselves. Imagine equipment that maintains its health and performance. And that learns from experience, just like humans.

Now, MYWAITM is crossing the Atlantic, with ambitious plans to expand its footprint by the end of 2024 with offices in Chicago and New York to showcase how its technology revolutionizes equipment capability within manufacturing, urban infrastructure, and healthcare.

Author: Riccardo Castagno

www.myw.ai

r.castagno@myw.ai