Trapped Key Interlocks and LOTO: rivals or team mates?

The LockOut TagOut procedure is a safety procedure used in many companies to avoid workplace accidents during maintenance of equipment. The idea behind this procedure is to prevent the

presence of residual energies from causing damage to workers due, for ex ample, to involuntary activation.

To prevent that, it is necessary to ensure that the machinery is off.

How does the LOTO procedure work? The LockOut TagOut procedure uses padlocks to isolate the panels from which it is possible to start the machinery : by positioning this padlock , and blocking these panels, it is avoided that there is an involuntary start by other workers.

Using the tag plate, it is clearly indicated that the machinery must not be activated and only the worker who is carrying it out will have the key to open the padlock. In some legislations the use of the LOTO procedure is contained in the laws.

What is the weakness of the LOTO procedure?

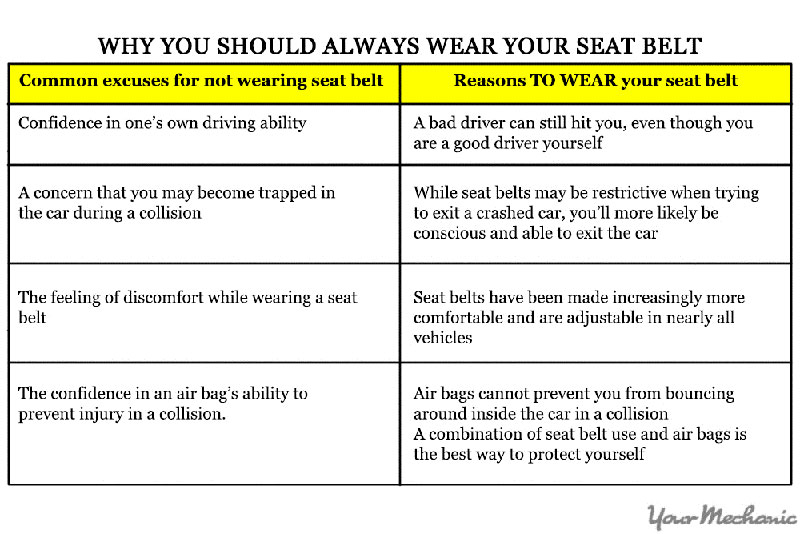

Very simple, it’s a procedure! And W hat a procedure is? “ The Procedure is a document that describes and provides evidence of a process…”. It means that the operator is requested to carry out the actions as defined and described. However, this does not translate into a forced obligation. Thus, the possibility of acting differently remains . That corresponds to perform dangerous actions . The car manual explicitly requests that you always wear a seat belt and warns about risks . If it is not used, does the car still work ? Yes it does . This is an example of a procedure; you are not physically obligated to behave as the procedure describes .

TKI to avoid circumvention Using TKI, a safe sequence of operations is enabled through transfer of keys that are either trapped or released in a predetermined order. Through interconnections (prefix “inter”) and sequential of key distribution it is possible to design mandatory sequences of actions; creating rigid sequences of activity which reduce the discretional actions of workers to zero. Companies have only two options: leave the application of safety procedures to the conscientiousness of the operators, or integrate them into the technical system. Arel® interlocks are exclusively mechanic or electromechanic . This choice is strictly related to their safety functions .

This way reduces the error rate to the minimum, lower than electric or electronic locks, and not generates false positives . TKI may break but they never allow to go on in danger.

Are they rivals or can work together and be team mates?

They are both the tool to mitigate, the level of risk , in different ways . LOTO system makes the operators responsible by providing an adequate method and the tools to implement it, leaving room for the presence of the “human factor”. TKI obliges the operators, physically forcing them, to carry out the procedure without leaving room for deviations and cancelling the “human factor”. For this reason, they should not be considered opponents but excellent tools for applying different security logics, they are intrinsically different.

However, in some cases they can work together. i.e. If there are several workers accessing in the same area at the same time it is possible to use tools for a “group LockOut”, in this way only the last operator that leave the hazardous area will be able to restart the machinery.