VI.PA. and Vipa Polimeri two leading companies in the field of manufacturing compounds

V I.PA . and Vipa Polimeri are two leading companies in the field of manufacturing compounds .

Both located in Ancarano, a small town in the core of Italy, they are solid family-companies and rep- resent a winning team for thermo- plastic compounds despite differing for typology of production.

V I.PA . was founded in 1969 and gets its name from its founder Mr. Vincenzo Paolini.

The only main focus is the production of P VC for which V I.PA . boasts thousands of formulations and a yearly production capacity of over 30.000 tons spread among Europe and all over the world thanks to a continuous attention on quality, service and customer care.

Besides the most common pvc us- age, V I.PA . offers a variety of specialties for many application fields including blends of P VC with other polymers in order to achieve special properties, such as:

HIGH VICAT when higher rigidity and shape stability at high temperatures is needed (both available either for extrusion and injection molding).

PHTALATES – FREE as a response to the current market demand for a more sustainable future in sensitive applications .

GREEN PVC free of those flame retardant additives that will be banned by International regulations and allow to have safe and clean Security Data Sheets .

THERMO EXPANDABLE FOR SEALING suitable for extrusion of strips for fire resisting doors .

RIGID EXPANDABLE compounds based on Innovative and optimized formulations suitable for ex trusion of “expanded” profiles for many different applications

SPECIAL FLEXIBLE GRADES FOR GAS HOSES at competitive prices with excellent performances in passing the tests required by various standards .

VERY HIGH FLAME RETARDANT materials able to reach very high levels of flame resistance, with LOI values up to 43-44%.

PVC FOR CPR highly flame resistant, low smoke and low chlorine emission.

P VC FOR AUTOMOTIVE UL 90 E 105° flame retardant grades able to pass severe ageing tests.

It is also worth a brief mention to other applications for EXTRUS ION/MOLDING for pipes, hoses, electrical accessories and footwear world.

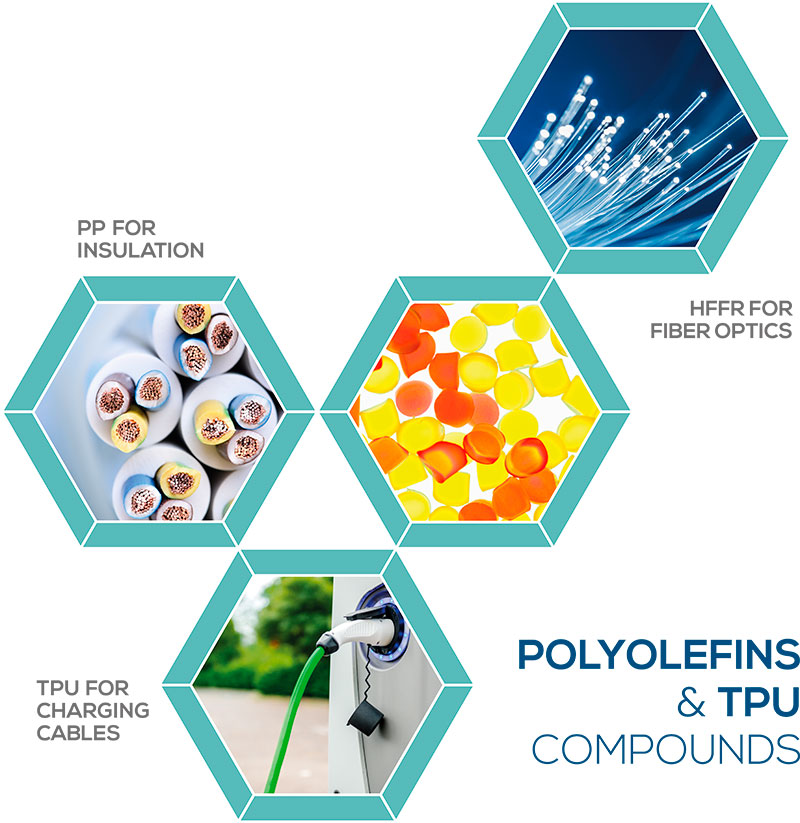

VIPA POLIMER I was then founded in 2004 to offer a wider and complete range of plastic solutions by increasing the portfolio with HFFR , PE , PP and TPU compounds, mainly for wire and cables .

HFFR: flex ible and very flexible, for CPR directive, with High fire/ Temperature/ Oil and hydrocarbons resistance. Sheathing for network & data cables (LAN cables) for CPR class B2, d1 for cables Cat 6+ , Cat 6A , Cat 6A+ , Cat 7+ , Cat 7A/7A

POLYPROPYLENE for insulation

POLYETHYLENE for low voltage cables, LDPE / MDPE for sheathing and HDPE for sheathing, insulation and physical foaming insulation for gas injection.

THERMOPLA STIC POLYURETHANE for sheathing of electrical cables, Gloss and Matt, Flame retardant V 0 and V 2, according to UL 94. A s a best seller good to mention the grade dedicated to EVC cable– sheathing E VM-1 for Electric Cables – C harging cables for Electric Vehicles acc .to EN 50620:2017

Nowadays V I.PA and V IPA POLIMERI reach a production capacity of over 50.000 t/yearly with a Quality system certified in accordance with IS O 9001:2015 as a result of a constant commitment to ensure a very high quality of products and accurate customer care.

The companies rely on an efficient commercial sales network spread throughout European and non-European markets, supported by the work of qualified agents and very well ex perienced staff.

Just back from a very positive and fruitful participation at Interwire 23 (Atlanta) and ready to hit the road all over the world!

www.vipa.it

www.vipapolimeri.it