EM&I’s Asset Integrity Services Saving Lives and Reducing Costs

Malta-based EM&I is a global provider of disruptive, innovative Asset Integrity Management Services, which mitigate safety risk , minimise operational impact, data, reduce carbon emissions, and save clients’ costs . With over 35 years’ experience in the offshore Oil & Gas floating production sector, inspecting and assuring integrity of floating production and storage units, EM&I is now expanding to the floating renewable energy production arena, particularly for Floating Offshore Wind (FOW ).

Innovative inspection services are underpinned by specialist Integrity Engineering to enable focused, efficient long term integrity management.

Drawing on collaboration in joint industry projects such as the Hull Inspection Techniques and Strategy (HITS ), and latterly FloWind JIPs, EM&I has developed proprietary technology and techniques which remove the requirement for diver intervention, and for physical entry in to confined spaces such as Cargo Oil, Water Ballast and LNG containment tanks .

As commercial diving is a high risk activity with frequent fatalities reported, EM&I has developed a suite of diverless techniques:

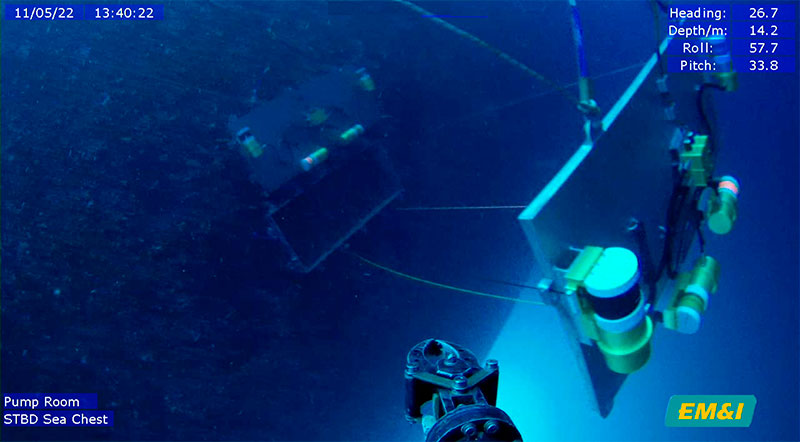

•ODIN ® diverless underwater inspection and complex repair using specialised, uniquely upgraded and high-performance integrity class ROVs, includes C lass-approved UWILD; visual inspection of the hull, cleaning, thickness measurement and Cathodic Protection survey with ROVs; and insertion of high quality cameras into operating sea lines to inspect valves while operating.

•The isolation of sea valves for safe repair or replacement using

LIMPET ® ‘intelligent’ sea chest blanking, and remote double block of overboard discharge lines with ROV insertion.

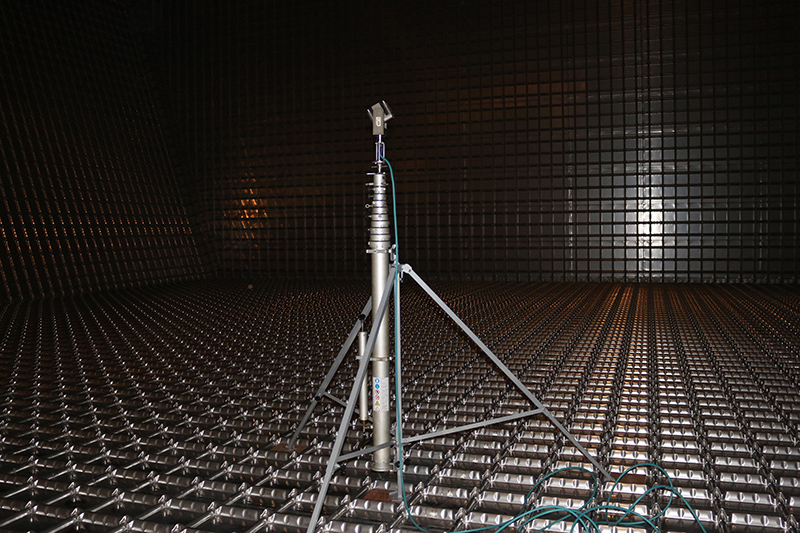

•Complex repairs, cropping and replacing steel below the water line using CLAM ® Acknowledging the high safety risk working in confined spaces and at height, NoMan PLUS ® enables remote inspection using high grade optical, laser scanning and UAV inspection techniques.

EM&I’s techniques mitigate human safety risk , reduce the impact on operations, reduce POB to free up bed spaces for other critical tasks, and reduce carbon emissions, as numbers to move are reduced. Capabilities are now adapted for FOW to assure long term integrity of the floating structures, enhancing insurability, bankability and investability for owners and operators .

For more information, see EM&I’s

website at www.emialliance.com,

or write to us at

info@emialliance.com