Wire-Laser Metal 3D Printing

A disruptive directed energy deposition technology by Meltio

Meltio off ers to reduce costs and manufacture metal parts locally with Robot Engine integration and its unique wire -laser 3D printing solutions. Metal 3D printing is opening a new era in industrial manufacturing.

Traditional processes for creating and repairing parts, with heavy molds and other techniques that require high investment costs and highly qualified training of professionals, are giving way to a new form of technology that allows lower costs, create reliable and detailed parts, contribute in the avoidance of generating as much waste as possible, which reduces the carbon footprint on the planet, enables local production, and raises productivity in production chains .

This new industrial paradigm is being pioneered by the Spanish multinational Meltio, based in Linares, in the Spanish province manufacture metal parts locally with Robot Engine integration and its unique wire -laser 3D printing solutions Metal 3D printing is opening a new era in industrial manufacturing.

Traditional processes for creating and repairing parts, with heavy molds and other techniques that require high investment costs and highly qualified training of professionals, are giving way to a new form of technology that allows lower costs, create reliable and detailed parts, contribute in the avoidance of generating as much waste as possible, which reduces the carbon footprint on the planet, enables local production, and raises productivity in production chains .

This new industrial paradigm is being pioneered by the Spanish multinational Meltio, based in Linares, in the Spanish province of Jaén. To this end, the company is developing unique wire-laser metal 3D printing solutions for industries that use metal parts in their manufacturing processes .

Meltio solutions will be present at Hannover Messe 2023 with our German partner Alphacam: Hall 17, Stand B40.

Industries such as automotive, aerospace, machine shops, railway, military, naval, mining, foundry, and any manufacturing process that requires welding, can use Meltio’s state-of-the-art technology : Wire- Laser Metal 3D printing. From prototyping to repairing tools, to creating and replacement of tools, and serial parts, which are easily ready to be manufactured with Meltio’s user-friendly technology.

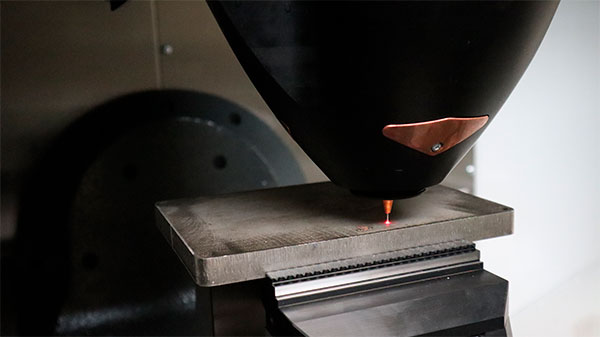

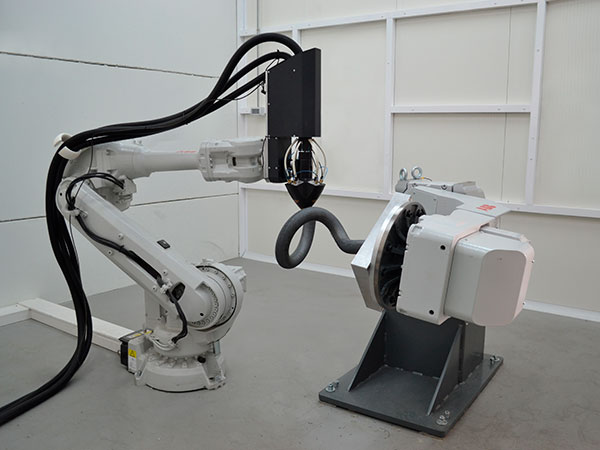

The process is simple: Laser Metal Deposition (LMD) technology is a Directed Energy Deposition (DED) process that functions by precisely stacking weld beads on top of one another, in powder or wire form, when introduced into the laser generated melt pool. Meltio’s technology comes packaged in a compact deposition head, hosted by multiple lasers and capable of processing wire and powder simultaneously. The bulk of the 3D printing process is built around wire, the safest, cleanest and easiest way to work with metal feedstock . Turn an ex isting CNC or robotic platform into a hybrid manufacturing system with no inherent size constraints .

Print dual wire for hard-facing or anti-corrosion applications, or wire and powder to create new alloys on the fly.

The same head can perform laser cladding with all the benefits of current welding wire technologies and Meltio offers three solutions: Meltio M450 3D printer; Meltio Engine CNC Integration and Meltio Engine Robot Integration. The molten filament of the material deposits layers of metal -like a traditional welding bead- and thanks to this technology, patented by Meltio, the creation of 100% metal parts is up to 10 times cheaper than other metal 3D printers. The resulting part only requires the final machining of critical areas without sintering or post-processing, and achieves a part with 99.998% density.

Meltio, in constant research, makes available to industries a wide catalog of materials such as Stainless Steel S S 316, PH17-4 (new material), 308, Mild S teel, NI718, NI625 (new material), TI64, Tool Steel H11, and has recently added to its catalog the new materials SS 17-4PH, TS H11, and Meltio Invar.

Meltio is emerging as the industry partner to bring disruptive advanced manufacturing technology solutions to industries around the world. Its new system goes beyond the manufacturing of metal parts, as it can complement by performing, retrofitting and replacing some of the traditional CNC systems or minimize their use or casting by performing retrofitting, in addition to offering its metal 3D printer.

Therefore, Meltio offers the same integrated head in 3 solutions depending on the industrial needs: the Meltio M450 printer; the Meltio Engine CNC Integration and the Meltio Engine Robot Integration. In addition to 3D printing, it can also perform repairs on parts, as if it were a sophisticated automated welding machine. The new technology developed by Meltio has been dubbed Wire-Laser Metal 3D printing, which has all the benefits of ex isting welding wire technology, as well as allowing the fabrication of a wide range of metallic materials . The Meltio head can also perform metal cladding functions (also known as laser cladding).

Contact Meltio for further information: info@meltio3d.com

Please get in touch for more information about Meltio in Hannover Messe 2023 here: www.meltio3d.com/itmg23