Terranova® drives the digitalizazion of fluid level control with Ultrasonic Level Switch Series ASL®

The new digital version of ASL® level switch, manufactured by Terranova® gives liquid level monitoring a new dimension never seen before.

No movement, no vibrations, no noises, with auto calibrating feature, this technology has no equals if compared to rotary or vibration measurements.

One device for all applications.

The control of level of the fluids is something we deal with in everyday activities. It happens when we open and then close the water tap before we enter the bath tub, or when we want the water tank that supplies the house to automatically refill, so that we can take a shower without remaining stuck in the very best moment, with shampoo in our eyes. Now expand this thinking to outside our houses, and think to how many applications are based on this simple principle.

The ASL® Level Switch manufactured by TERRANOVA® has been innovated with a new digital heart, so that one level switch can suit all applications.

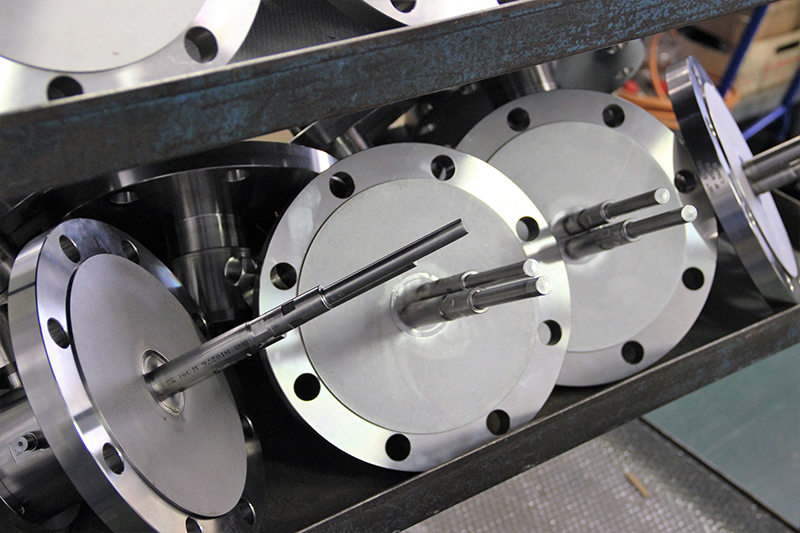

The measuring principle is based on an electronic board that generates acoustic waves directly addressed to an integrated probe. The probe is the instrument sensor and the waves are dispersed in the fluid in case of submersion in liquid or bounced back in case of dryness.

The new ASL® elaborates the signal in a more stable and robust way, making the instrument more performant and adjustable for all type of fluids, temperature ranges and wetted parts materials. A number of devices that previously were in need of specific calibrations (i.e., water is different from oil, that is different from Soda, etc..), can now be gathered in only one smart device, able to understand the needed sensitivity and thresholds setting.

This new ASL® digital version is also matched with a calibration software, called USC®, dedicated to all field operators. With this new software it is possible to set the operating modes, to manage a big number of parameters, like output type and values (current, frequency or relay), the type of operating (direct or reverse), the probe sensitivity, and to execute an automatic calibration cycle using the Autocalibration function.

We believe the advantages of our technology are now enough from a mere technical point of view to drive to a change of technology in most of applications.

The number of potential applications is huge: the control of level in beverages tanks in the food industry, the control of level of oil products in Oil and Energies market, the control of level in all the municipalities, the control of ballast tanks and cargo tanks of ships, and anywhere there is a need of regulating the fluid level inside tanks.

For more information:

www.terranova-instruments.com