When the success is a matter of a few microns

Have you ever wondered how you get the smooth sliding of the cylinders of your car? Or the perfect rotation of the gears of your mechanical wristwatch?

The answer is a unique process called “honing”.

Honing is somehow an art rather than the more widely spread machining, it is achieved through the use of stones, carefully selected to condition the metal to get an accurate, even surface. It is usually the last step of many production processes and, however, the most critical where tight tolerances of mechanical coupling do affect the functionality or the performance. Honing is in fact the most precise finishing, capable to achieve finishing with errors lower than 1 μm and roughness lower than 0,01 μm. For this reason, honing is used for the production of almost all hydraulic devices, gears, power transmissions, engines, gear boxes, bearings, sleeves, weapons, valves, oil pipes, food processing machines, medical devices and in many other applications. In general, whenever there is a sliding between cylindrical surfaces, honing is the process that most likely would grant the best performance, while minimizing the working time and cost.

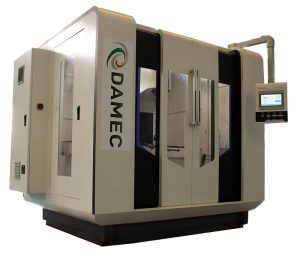

Honing can achieve a finishing grade higher than grinding and, in several cases, this latter can be replaced since honing is much more easier and cost- effective. Damec is the leading Italian manufacturer of honing machines and, in general, the main developer of customized honing solutions. Our capability benefits from the thirty-five years of experience in the field of our technicians and the everyday passion which lead us to face the new challenges of today market.

The pursue of new solutions, in fact, requires constant application and the investigation of new technologies.

In many cases – refers Mr. Maggioni, Damec CTO – “we have to develop and build specific tools to get the result. Only experience can lead us to identify the most suitable techniques to be developed into a prototype and then tested against performance”.

One of the most distinctive features of Damec is the thoroughness of service. “We take care of our Customer’s whole process, trying to identify the solutions that best fit his management. Every new machine, device or tool is fully validated before it leaves our premise” emphasizes again Mr. Maggioni. For these reasons, Damec is considered a reliable partner form his Customers, constantly increasing his presence in the market and to provide qualified support through all the plant lifecycle. Where the difference between success and failure is a matter of a few microns, here is the playground for Damec to demonstrate his capabilities.

For more information:

www.damec.eu

info@damec.eu