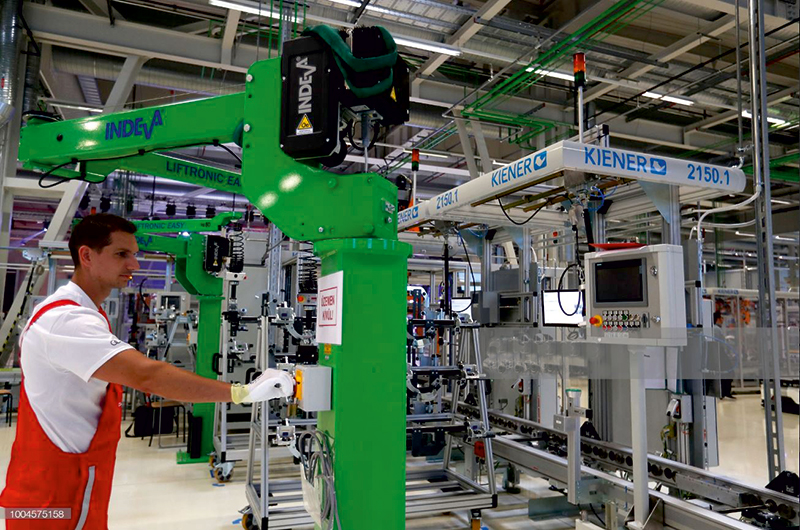

INDEVA manipulators comply with the modern and most demanding Automotive industry production standards

The automotive industry is undoubtedly among the most advanced in applying the latest ergonomics principles in their technology choices and process setting.

This industry has also adopted very strict guidelines regarding safety and ergonomics for operators, thus requiring advanced technology that ensures precise, fast and smooth movements, with rotations and special sensors.

Traditional manipulators have some limitations to achieve these requirements, due to the pneumatic control technology. Where load positioning precision and good load visibility are required or for repetitive and frequent movements, a manipulator featuring lightweight, compact design and above all true auto-balancing technology, is crucial. The auto-weight detection and auto-balancing feature of an INDEVA® electronically controlled manipulator allows the real time reaction at the very touch of the operator with no need of extra effort by the operator to counteract the inertia and gravity forces in the first detachment of the load from its support and in the change of direction along the Z axis.

World leader tire manufacturers with highly efficient tire manufacturing process repeatedly choose INDEVA® manipulators for handling loads in different areas. From simple to more complex work cycles the INDEVA® Intelligent Devices for Handling are the leading-edge technology for ergonomic and safe tire handling. Scaglia INDEVA® has supplied hundreds of lift assist devices for handling dashboards to many companies within the automotive industry worldwide. The Automotive industry relies on INDEVA for its great expertise in the design of custom end effectors for handling dashboards of different shapes and sizes.

The Indeva Manipulators are Industry 4.0 compliant.

An INDEVA® (Intelligent Device for Handling of the Liftronic® Series) can exchange data with the customer IT system through the company wi-fi network and allows visualization of the manipulator activity by means of interface software.

Data communication capability is a feature required for machines in industry 4.0 Main advantages of the applications with 1 or more INDEVA Manipulators interconnected:

Enhanced production flexibility: flexibility in production process planning makes it possible to produce more product types in less time at lower costs. Mixing different products in one production chain is achievable only if intelligently controlled by a production management system that can interact with operator and machines, including manipulators.

Supervision of manipulator: INDEVA® Gateway allows to monitor manipulator status both from inside and outside the Company network and scheduling maintenance on the basis of actual work conditions.

Monitoring worker’s effort and optimization of ergonomics: INDEVA® Gateway allows to monitor and control the operator’s effort and to set use conditions to satisfy the request for both more productivity and more ergonomics for the operator.

For more information please visit:

www.indevagroup.com