Atos: men, ideas and technologies at work, to always achieve exciting goals

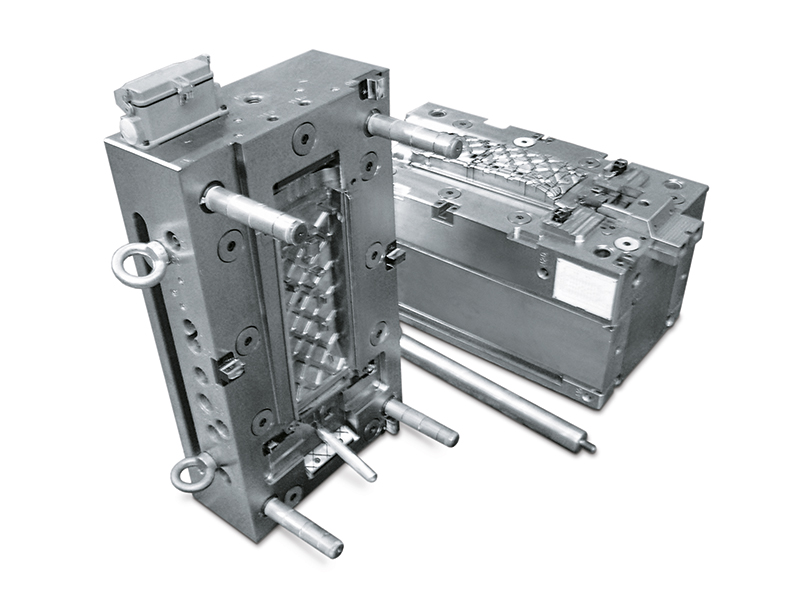

Set in San Quirino (North East Italy) A.T.O.S. SRL is specialized since 2000 in the design and production of injection moulds for plastic and rubber items.

OUR TEAM

Thanks to our in-house project dept. and our specific softwares, we are able to quickly reply to all enquiries, support and involve the customer through all the manufacturing phases. Our know-how, both in mould design and production and in final plastic articles, allows us to carefully evaluate and analyse every single order, to propose the best alternatives and to solve both technical and organizing problems in order to offer the best solution.

All that is possible thanks to the close cooperation within our staff and a constant dialogue with the customer.

We are a medium-sized company with a staff of fifteen employees, motivated, empathetic, always moved by a proactive spirit.

Being not a big-sized company this allows us to be highly flexible during all processing phases, from design to delivery.

We love to tailor the business relation with every single customer in order to meet his reality, requests and expectations.

We are proud of our ‘MADE IN ITALY’ product, which is appreciated both in Italy and abroad.

OUR PUNCTUALITY

In our 20-year activity we have always met the agreed delivery terms: our statistics show a 0,00% delays of more than one week and a 0,008% delay of more than three days.

This goal, that we have established from the very beginning of our activity and that we want to keep in the future, represents our main characteristic as well as fulfilling our customers’ satisfaction.

OUR FIELDS, OUR TECHNOLOGY

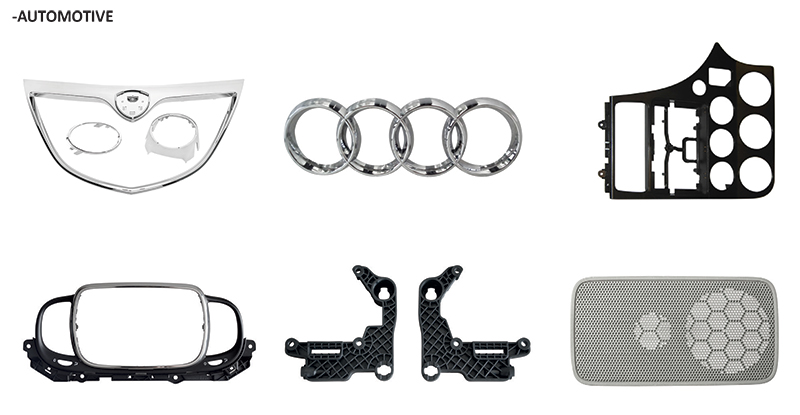

We face challenges in the most different sectors: from automotive, household appliances, packaging, lighting to phone industry, fastening systems, industrial transport, sport & leisure; both of technical and highly aesthetical articles, with complex geometries, high-quality and precision items, with surface finishing such as erosion, polishing, chrome plating, painting and photoengraving. In recent years we have also expanded in the rubber and die casting sectors.

Thanks to our extreme care in every detail, we offer moulds perfect for any sector, both for products of technical peculiarities and to niche products, of high quality and high design.

We manufacture the following injection moulds: 1, 2 and 3k, rotary, transfer, cube moulds, with IML, multi-cavity (up to 64), for over-moulding and thermosetting. Moulds are supplied ready to use after being tested, with test reports and materials certification. On request we also supply additional try-outs and small production series. Our production range includes prototype aluminium moulds with automatic and semi-automatic functioning, pilot moulds, low-cost moulds for small runs and with tight specifications.

The maximum dimensions of the moulds we produce are mm. 900×1200/1400, with a total weight of 5,000 kg, for parts from 2 to 1500 grams.

We also provide maintenance, repairing and adjustment services for moulds produced by us and for third party moulds, produce mould parts and execute precision machining in general.

OUR MACHINERY

Our machinery is distributed on an area of 1200 square meters, recently upgraded with one simultaneous 5-axis milling machine with six pallet changers and consists of three CNC milling machines, one 5-axis CNC milling machine, one CNC EDM machine, two WIRE EDM

machines, one grinding machine, one lathe and two drill machines.

‘MEN, IDEAS, TECHNOLOGY AT WORK’

Our motto thus summarizes the union among the human intellect, ideas and technologies aimed to achieve always increasingly exciting goals.

Filter produced with our mould.

Filter produced with our mould.

Peculiarity of this part is the holes diameter: only 0.9 mm!

Here are some examples of products made with moulds designed and built by us:

For more information please visit:

www.atositalia.com

sales@atositalia.com