TMA Winches Just Winches Since 1987

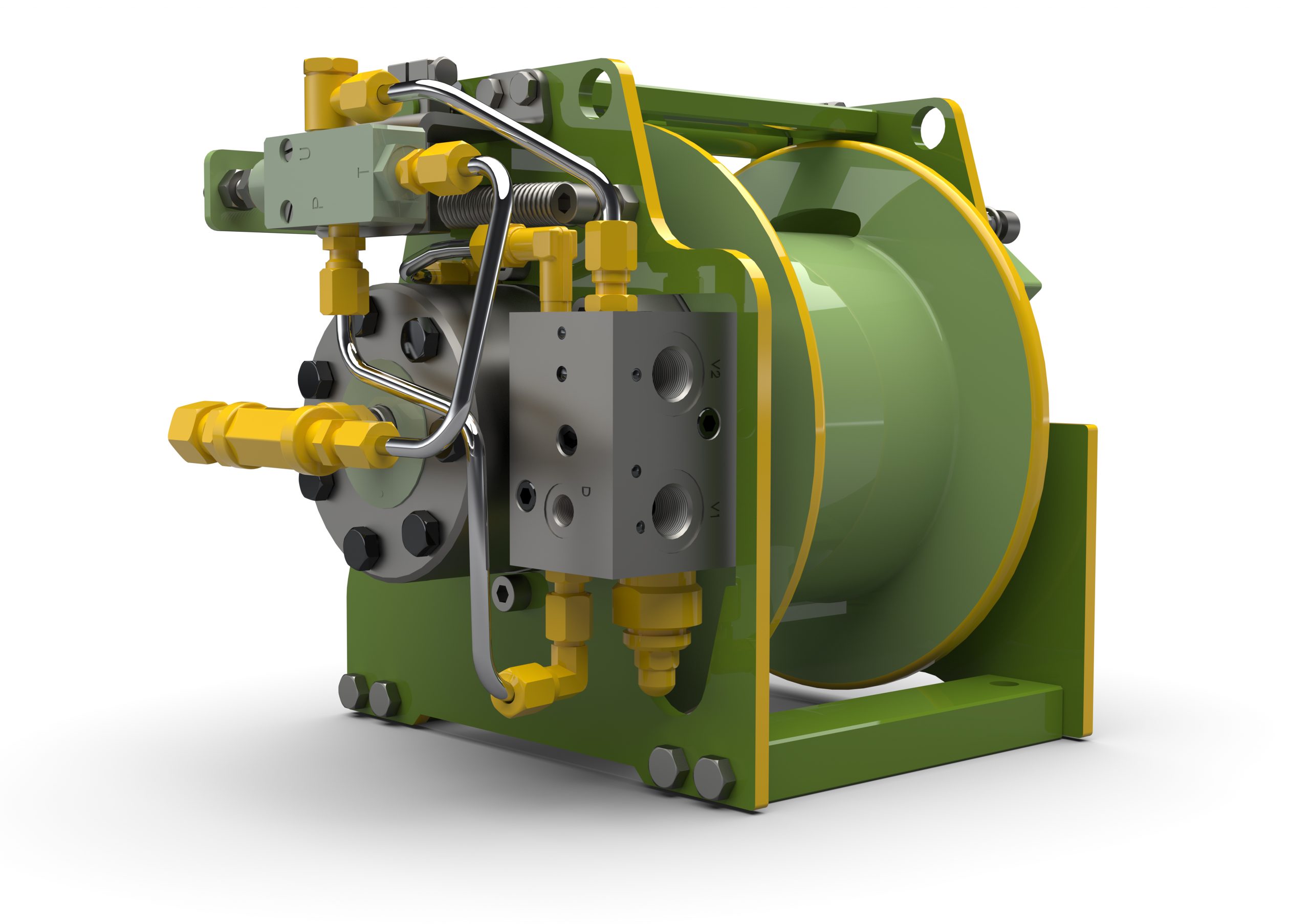

TMA designs and builds hoisting and pulling winches for every application and for several sectors: compact winches for truck cranes, high speed winches for mobile cranes, special winches for drilling machines, customized winches for marine application and special low magnetism winches for military sector.

One of TMA strong points is represented by hoisting winches for drilling and construction machines, designed and manufactured in order to be sturdy and reliable, as these applications require components able to guarantee the maximum reliability in the most challenging working

environment.

TMA has a great deal of experience in this market, with a range of winches specially designed for such applications.

Small size winches are very compact, with gears, motor and brake integrated in the drum, whilst the larger winches have a welded frame with increased thickness, improving the stiffness and better tolerating eventual deformations of the machine.

Moreover, TMA can develop bespoke winches to fulfill every customer requirement.

Of course, a complete range of accessories can be added to winches according to Customers’ requirements, always after feasibility studies conducted by our technical department.

Just to mention a few: lower limit switch, revolution counter, anti-slack rope system, backstop device, ratchet & pawl, and spooling devices are just a sample of the accessories that can be mounted on our winches.

Load limiting and load detection devices are very reliable systems providing results with extreme accuracy.

TMA can also provide winches to comply with ATEX directive for zones 1 and 2.

Especially thought for drilling applications, TMA can supply a complete range of wireline winches. These winches can store a huge quantity of rope and reach very high spooling speed.

The spooling device and special grooving in the drum assure correct spooling of the rope.

HIGH RELIABILITY

Our winches minimize maintenance activity whilst, at the same time, assuring the highest levels of reliability. Each winch is fully tested before delivery and the test results are recorded with the winch serial number. All data are available and regularly sent to Customers once the winch has been delivered.

The TMA quality control system is certified and the organization continuously improved, with the results being demonstrated by the high quality level of the winches.