ASSET INTEGRITY a growing need which is becoming a basic setting for any project

Nowdays, while we all fight with the Pandemia and the Energy Transition challenges, the global demand on asset integrity analysis is increasing, especially to evaluate possible production changes, rehabilitation, CO2 emissions reductions and improvements.

The topic has changed from a mere maintainability and reliability approach; the Oil Price instability along to the Energy Transition is leading the Contractors and the Operators to move towards a circular economy to re-use before dismantling.

Standardized approaches to the Asset Integrity like failure analysis, reliability studies, “fitness for service”, residual plant life extension, risk-based inspections are now strongly pressed by the need for technological renovation and we believe the Digital Twin would play the lead of this revolutionary development.

A digital Twin is a 3D high realistic and data driven soft copy of the asset, it can be created along the design phase as well as on the existing facilities, starting by a 3D CAD model or by the laser scanning.

Digital twin is widely recognized as an upcoming standardized step in the Oil & Gas Industry, starting by its first slogan definition: “the single point of truth”.

Besides the effectiveness of a slogan, the above definition is rooted in a very important basic concept: A Digital Twin becomes the ergonomic project box, where design, erection, commissioning, operation and maintenance phases fall into.

Thanks to its agnostic data driven set up, billions of data find a suitable and traceable path for actual and future use.

The same pattern is valid for the operational parameters thanks to a full integration with the Controlling Systems, that was only simulated during the design phase but it can go “LIVE” now along operations with the Digital Twin.

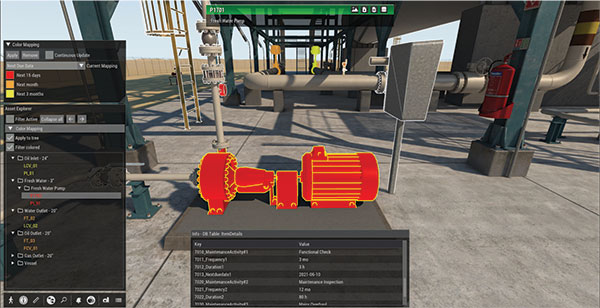

At ISS International SpA we’ve deloped internal patented technology to realize PYXIS®, a multidisciplinary environment designed for Oil&Gas industry, where Asset Management and Analysis is a consequence of the previous phases and all information and data find proper

and easy manageable location in the Digital Twin.

PYXIS® is a modern and secure web platform based on the awarded internal technology for Digital Twin, offering Engineering, Training, Maintenance and Site Services around the Asset Digital copy, where information’s flow together.

Any CAD size and format, billions of metadata can be converted in a virtual copy of the asset quickly and for further implementation even from different contractors and vendors by remote secure access.

Information like layouts, data sheets, P&IDs, MR, PR, PO, vendor’s manuals, training plan and all its attachments, erection progress, permit to work, schedule and all required data. All these information remains easily manageable and retrievable being just a click away on the real and digital representation of your asset. Let’s imagine clicking on a package, equipment of the digital twin and finding all the design information, erection and commissioning or maintenance reports or its actual working parameters, together with any possible alarm of the control system (DCS, PLC, …). Moreover, you can be just a click away from finding a proper and updated interactive and immersive training module to simulate a real field and/or control room operation scenario in a complete safe and remote manner.

This is the way the Asset Integrity makes a step further, from a preventive standalone activity to a standard integrated analysis for any project development. It became a consequence of project completion, always.

Take your informed decision with the Data available in your LIVE digital twin representation of your Asset!

Digital Twin is the best completion for the asset integrity making available detailed performance data by interfacing with OTS and many other data that can allow to create KPI for single equipment, packages as well as the whole asset. KPI, that can support the next upcoming

step: the statistical design.

Statistical Design is the next stage where who won’t be able to govern its historical data risks to be cut out.

We make a step ahead, with an in-house 100% Italian patented technology available to support present and future developments, available for demo and applications.