Gear metering pumps, Gear transfer pumps, Piston metering pumps, Diaphragm metering pumps

Pompe Cucchi is a Company of design and production of gear transfer pumps, gear metering pumps, piston and diaphragm metering pumps and has been present since 1948 in metering and fluid transfer fields.

Pompe Cucchi works in accordance with Quality System ISO 9001 (2015). The pumps are conformed to the Machinery Directory 2006/42/EC, 2014/30/UE, 2014/35/UE, 2004/108/EC and UNI EN ISO 12100, 13732-1, 809. On request we can supply pumps conformed to the directory 2014/34/UE (ATEX), API 676, NACE MR 0175. All our pumps are certified TRCU010 and TRCU012.

In addition to its production, Pompe Cucchi is Italian distributor of the Jabsco industrial line pumps, GRACO pneumatic diaphragm pumps and Grun-Pumpen drum pumps. Engineering, experience, expertise, passion and dedication, this is the formula for Pompe Cucchi works every day to offer the best product and service.

See the production range in www.pompecucchi.it

Back ground

Pompe Cucchi is present in the pumps field since 1948.

Founded as a manufacturer of standard gear pumps for viscous and lubricants liquid and today, thanks to the realization of innovative projects, and the continue research of new materials and surface treatment, offers products that allow to pump and dosing non-lubricating fluids with extremely low viscosity with high pressures.

Our products are marketed by a network of national agents and a num-ber of dealer around the world. The project is managed by a team of engineers using last generation CAD stations.

Production

Pompe Cucchi has installed a new control numerically controlled machining centre with 18 pallets that can work 24 hours/day also not witnessed (without operator) equipped with supervising software for the management, control and integration of MCM’s production systems. This machine has a robotized tool magazine (of 400 tools).

Special execution

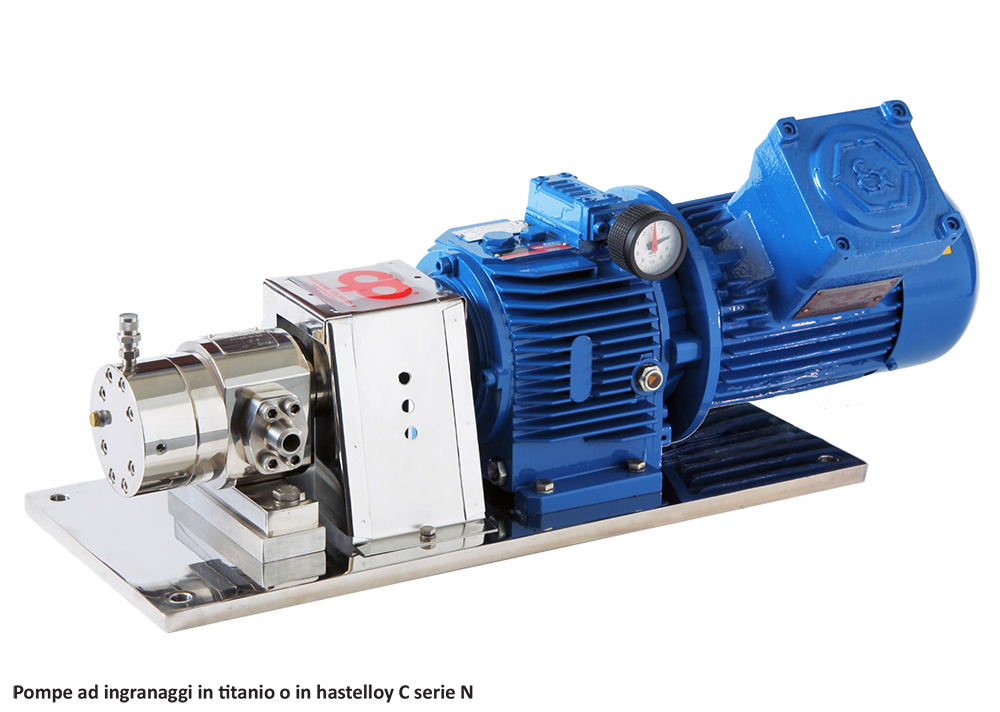

The ongoing development of our pumps project and new materials research allowed us to produce pumps in TITANIUM and in HASTELLOY C. Executions can be differentiated with the installation of single mechanical seals, double in tandem, double back to back or magnetic coupling also ATEX certified. We have also developed the insertion of bushings and wear plates made of tungsten carbide and chromium oxide-covered shafts in some size of dosing pumps series N used for metering of slightly abrasive products. On food sector, we have also the option to fit all components FDA certified.

Surface heat treatments

The new thermochemical treatments have given to gears and shafts, of some pumps range, surface hardness up to 4000 Vickers allowing new applications until a few years ago thought impossible.

For more information:

www.pompecucchi.it

sales@pompecucchi.it