Corrugated Carton Converting Machines Innovating Tradition

A lightweight and fully recyclable package that offers great protection is made possible by the BOXMASTER carton converter and XC32.1 stitcher.

A lightweight and fully recyclable package that offers great protection is made possible by the BOXMASTER carton converter and XC32.1 stitcher.

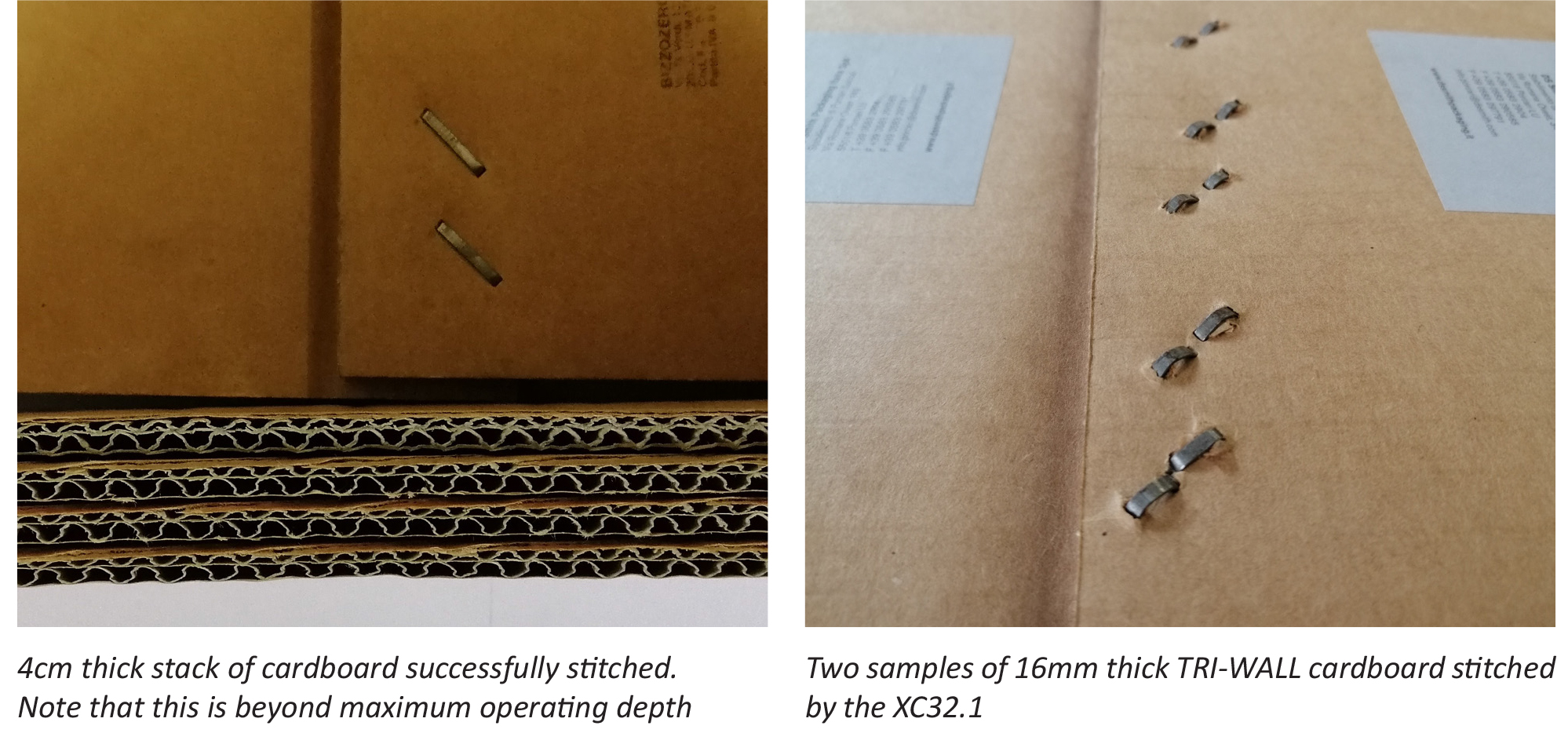

Orders for packaging come in all shapes and sizes, which makes versatility essential. Along with that, BIZZOZERO’s converting lines give you outright performance to reach where others can’t. Think of a world where heavy, slow production, expensive woodchip cases are replaced with more eco-friendly, cheaper, faster production TRI-WALL cardboard boxes that are just as sturdy and even absorb mechanical shocks.

THE LINE

Each of BIZZOZERO’s machines is great value by itself, but the total is greater than the sum of the parts. Wether you already have your own line and want to make a nice addition or you need a completely new line, BIZZOZERO has got you covered.

The production line is tailored to your needs: we can provide all that’s needed to go from a stack of cardboard sheets to a stack of folded boxes that are only waiting to be filled. Layouts for this production line are tailored according to your available space and logistics and you can get creative with which “building blocks” you want to use and where to lay them relative to each others. In its most popular configuration, the raw material is automatically fed along the grain into the JUMBO flexographic printer, then entering the BOXMASTER, which performs all the slits, cuts, creases, slots and an additional monochromatic print to have a fully finished sheet. For two-piece boxes, the sheet then passes on to an operator who feeds them against the grain into the semiautomatic XC32.1 stitcher that ejects them onto an elevator and ultimately on a stacker.

THE DOUBLE HEAD STITCHER

Everybody knows we make the best stitchers.

Few know that we’ve just updated them. The new XC32.1 stitcher for heavy carton is still capable of stitching and gluing the thickest TRI WALL sheets, but now does so more reliably, faster, with better user interface and computer connectivity, using less energy and requiring less maintenance. All thanks to its SEVIO

remote control and its electronically coordinated brushless motors. The advantages are evident: the outgoing machine offered top notch stitching quality and was driven by a single motor that distributed its power through a set of clutches and mechanical drives, but it didn’t last forever. The clutch system has mechanical losses that sap energy, wasting it into heat and wear; after time, it wears out just like any clutch in a typical passenger car.

The results are an imprecise stitch, an increased energy consumption and the production of particulate matter from the clutch material being worn. We did away with this system altogether. Shifting from a mechanical drive to more automated, electronically controlled brushless motor units, has also increased reliability: where you then needed a mechanic to inspect the drivetrain’s condition, now the machine’s health status can be remotely inspected. A machine that is forever young, whose memory and interconnectivity won’t fail you.

A taping feature is coming soon for this model.

Combine this with the undisputed versatility of the BOXMASTER to make over a hundred FEFCO codes with a great range of sizes going all the way up to the biggest boxes available.

The size of the sheets you can work with these two machines go from a minimum of 360x620mm to a maximum of 2810x10000mm

SET UP TIMES

They’re shorter than ever. A versatile machine is useless if its setup takes ages. Programs for stitching, printing and cutting are easily programmable via touch screen interface and can be memorised to access them when needed. Positioning of the guides, feeding and stacking operations are completely automated. Cutting tools are pneumatically locked and take seconds to be relocated.

Stitching heads move on motorized carts and the stem depth is fully adjustable without changing any component.

INDUSTRY 4.0

An important lesson that the industry has learned is that wherever you can avoid humans from doing repetitive, alienating tasks, you should have a computer to do the tasks instead. Don’t waste time, let the machines themselves communicate with your management software.

Bizzozero brings you straight into the fourth industrial revolution by allowing you to do just that. You’ll be able to register every manufacturing parameter and have your production programs always ready at hand. You can count on the reliability of these machines and if that wasn’t enough, remote diagnostics ensure every error is promptly corrected. And if that wasn’t enough still, spares and expert assistance will never leave you stranded, wherever you are in the world.

QUALITY WARRANTED BY 82 YEARS OF EXPERIENCE MADE IN ITALY