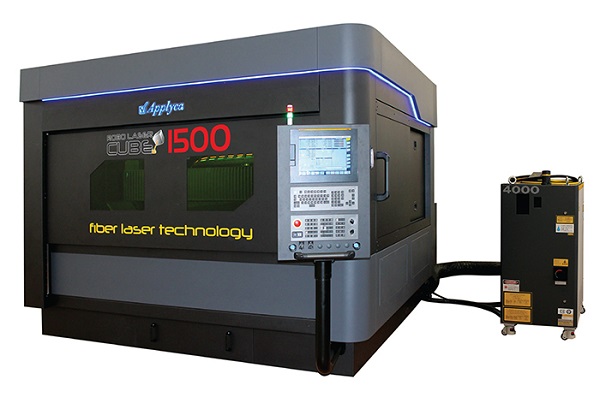

Applyca ROBO LASE CUBE Make the difference: the high-quality, small and compact cutting cells

Companies with complete production of machinery and the need for new ones. Robo Laser CUBE stands out from the moment it enters the production departments, taking up little space. It is already active in a 1,500 x 1,500 mm work field, ready to integrate into the production process with an industry 4.0 approach and customizable to meet the exact needs of the client.

Robo Laser CUBE, in fact, was conceived by the Italian Applyca, connected by some professionals who shared the long personal experience in the machine tool sector and assistance at specialized companies. For this reason, Robo Laser CUBE and its custom-made sisters are first of all strong and robust machine tools, heavy and installed on a rigid base so as to avoid that they themselves cause errors in cutting. They are then designed for a high-end market, which requires high precision cuts with fiber la- ser cutting. They are built with the best of the available components, for example Fanuc (advantaged also in the maintenance phase for the widespread assistance net-work). Added to this is the CNC control software that is applied by Applyca itself.

The CNC and source lasers are made by Fanuc guarantee of impeccable communication between the two devices.

It also takes place internally, via optical fiber, and is therefore immune to disturbances.

In addition to the precision up to H7 tolerance of fiber laser cutting and the construction precautions already described, the machine is also very fast. In fact, it has linear motors and a very light Y, in aluminum or carbon fiber, which is even more performing. It gives the possibility to select a new cutting phase in less than 5 seconds and to launch different orders in the same worksheet.

The different orders can be managed through automatic recognition during the unloading phase by the assigned robot, which can be installed by Applyca.

If these bases are combined with all-round customization, thanks to a multidisciplinary team that integrates very dif- ferent specialist skills (robotics, lasers, PLC, CNC and HMI software, vision systems, mechanics, pneumatics, hydraulics, electrical panel design), the possibility of using its Robo Laser CUBE 24 hours a day, is a convincing answer for companies that require precision in cutting and performance in terms of speed and durability, in particular for the reality they experience over three daily shifts.