Safety in Hazardous Areas Reliability, Quality and Innovation in Explosion-Proof equipment on a worldwide level

Since 1973… MIRETTI GROUP engineering expertise and technical experience

Miretti Explosion Proof Systems and components for diesel engines and mobile vehicles of the Oil&Gas sector.

“Can an engine work in safety in areas classified as hazardous?” The answer is yes. This is only one of the most frequently asked questions when you need to make your own equipment safe (“explosion proof protected”) – be these diesel engines or industrial vehicles – for “Hazardous Areas”. The Oil&Gas sector On/ Off Shore, petrochemical industries, oil rigs etc… all locations in which an engine or a mobile vehicle must work in safety.

The consequences might otherwise be catastrophic. Another frequently question: “Is the equipment really Explosion Proof?” The answer is yes. It does how ever need to emphasized that it is best to rely on a partner with technical skills and know-how to support the customer during all stages of planning, production, after sales/spare parts. It is in fact from aspects like these that the reliability of a brand committed to Explosion Protection derives. On this understanding, Miretti Group has been operating internationally for over 45 years.

When we talk about Explosion-Proof we mean Safety (for people, vehicles and the environment) in areas at risk of explosion.

Specifically, we intend to make all equipment safe according to the Reference Directives (that may differ from Country to Country: ATEX, IECEX, CNEX, FM, NEC, EAC Ex… ) eliminating any possible cause of ignition, spark or heat that may generate an explosion.

No intervention can be defined as standard and it is for this reason also that over the years Miretti has invested in Research and Development by making use of a technical office (with both mechanical and electrical engineers) and a certification department both inside the Company

itself.

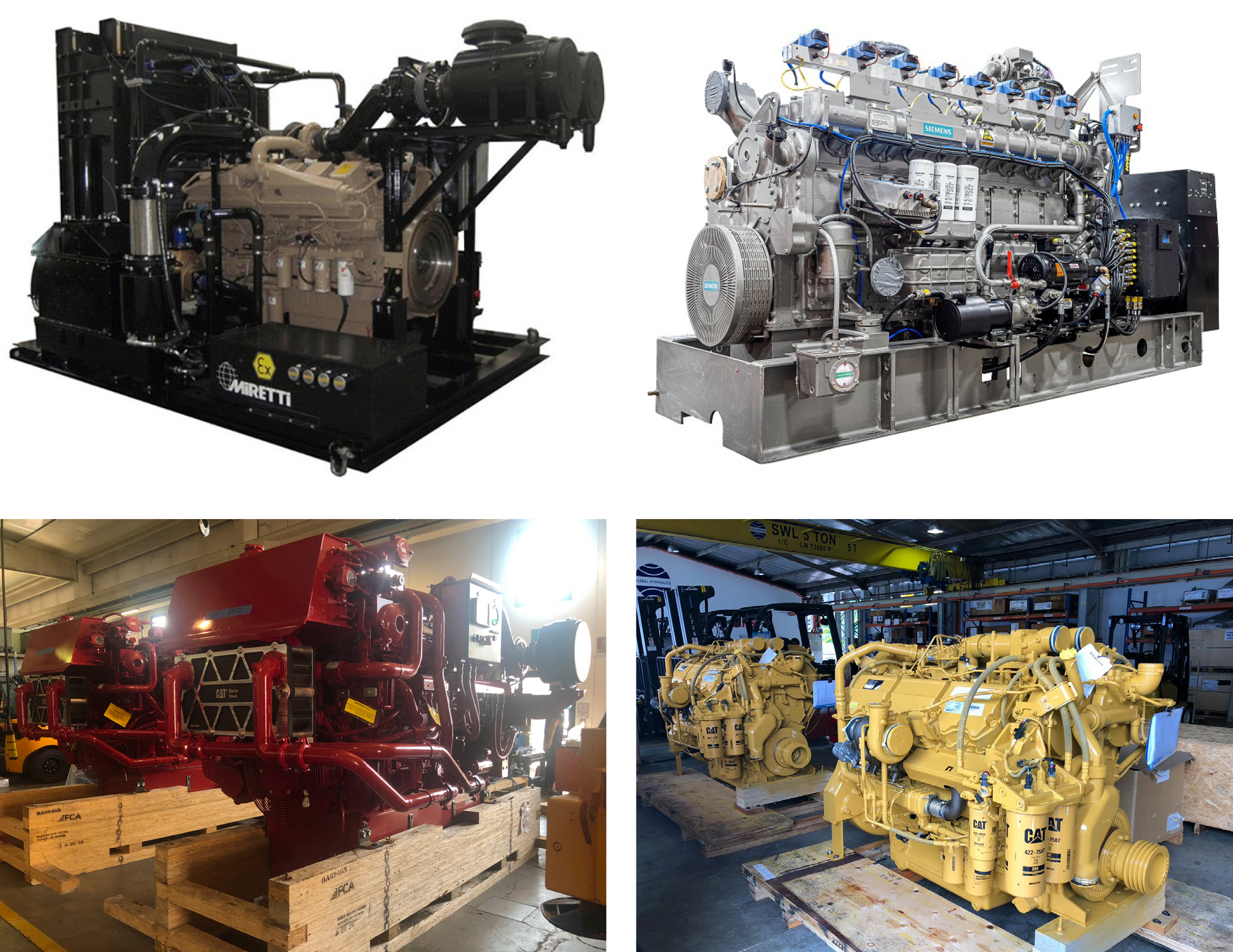

Communication with the customer is constant; in fact, the Miretti Team maintains a continuous exchange of information with the customer. “There are no preclusions

– says Angelo Miretti, CEO of Miretti Group – We convert any engine. I only remember some brands: Caterpillar, Cummins, Atlas Copco, Volvo, Deutz, Perkins, MTU, John Deere, JCB, FPT etc… We work independently and can

support our customers around the world thanks to our thorough knowledge of the regulations. We, as Miretti, are actively involved in many international technical committees aimed at discussing current regulations and new standards for the future. This is certainly an added value

that is recognized to us. We are a company with a global approach to the topic of <hazardous areas> thanks to the opening of production plants and commercial offices all over the world”.

Dealing with Explosion-Proof also means talking about efficient, modern and advanced design solutions capable of responding to the needs of today’s market. “Explosion-Proofing is often a forced choice – continues Ange-

lo Miretti – It is, in fact, the legislation that requires you to follow certain standards of protection. It is important to keep the customer informed and educate him about the Explosion-Proof product, which is not always so well

known.” Miretti works to ensure that the Explosion Proof conversions are “at the service” of the equipment on which they are mounted. The Miretti “explosion proof/ flameproof” conversions try not to alter the original com-

ponents and parts of the OEM unit whilst preserving the layout, ergonomics and performance of the original engine as much as possible. “So where is the difference?”

“The conversion is a meticulous procedure – says Matteo Stefanini, global sales and marketing director of Miretti Group – often involving the almost total dismantling of the unit in order to provide solutions to allow them to operate in hazardous areas”.

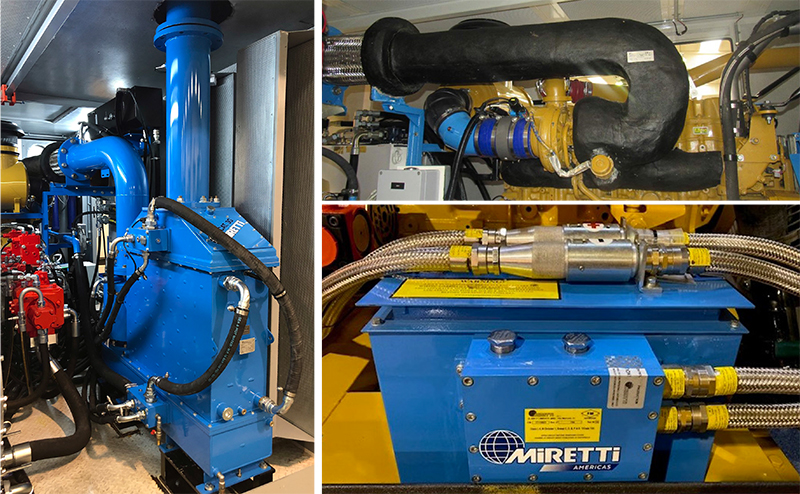

Miretti can convert both industrial and marine engines, Tier 3 and Tier 4, collaborating closely with the major OEMs. Typical processes on a diesel engine include interventions on the inlet and exhaust lines, insulation of

hot surfaces, cooling of exhaust gases, encapsulation of sparking components, antistatic treatment of some surfaces. “We’re flexible in response to the market demands – continues Matteo Stefanini – We can offer pre-assembled packages and kits to be assembled on site by the cus-

tomer, with our support. Thanks to our technical office, we can also offer 100% customized solutions with <ad hoc> designs allowing us to gain insight about any eventual problems that might arise, however complex, such as spaces or structural limits”.

Many innovative solutions are part of the Miretti Explosion-Proof world. Amongst these is the Miretti FilterEx an innovative, ‘compact’ and certified

exhaust cooling system with integral self- cleaning exhaust flame and

spark arrestors. Placed before the exchanger in contact with very hot gases, it is an innovative system as it allows maximum engine operation, reducing the time required for machine downtime.

The self-cleaning flame extinguisher/spark arrestor can work for about 1,000 hours before inspection and any cleaning is required. This is an approach that we can define alternative as it reduces the costly maintenance interventions of conventional systems. Another innovative solution is represented by the Miretti CoatEx, which provides a thermal barrier between the hot surfaces of the engine (such as, for example, the turbocharger and the exhaust manifold) and the external atmosphere. With its use, all the original components can be preserved maintaining their operation unchanged. In addition, the system – patented by Miretti – has recently been subjected to a series of strict resistance tests which have confirmed its efficiency.

In these two solutions, taken as examples, we find one of the key aspects of the company philosophy: working to provide a tangible advantage to the customer. Technical Know-How, knowledge of regulations, continuous R&D,

Support and Assistance always and everywhere (even in webinar mode): these are some of the levers that make the Miretti Group a reference in the Explosion-Proof world, always careful to provide the most performing, efficient and advantageous solution.