Thread Rolling Machine Model 2RP30 CNC EVO

Our company is approaching the big evolution of the global market, aiming to the completely renovated models of rolling machineries, being focused on a wide range of machines (up to 150 Tons), the use of new technologies, the fully automatic machine’s adjustment and new developed solution for integrated automation.

Our company is approaching the big evolution of the global market, aiming to the completely renovated models of rolling machineries, being focused on a wide range of machines (up to 150 Tons), the use of new technologies, the fully automatic machine’s adjustment and new developed solution for integrated automation.

ORT has introduced EVO models, the new generation of machines featured by a high sturdiness and compact frame with several innovative technical solutions for a quick set-up and friendly use.

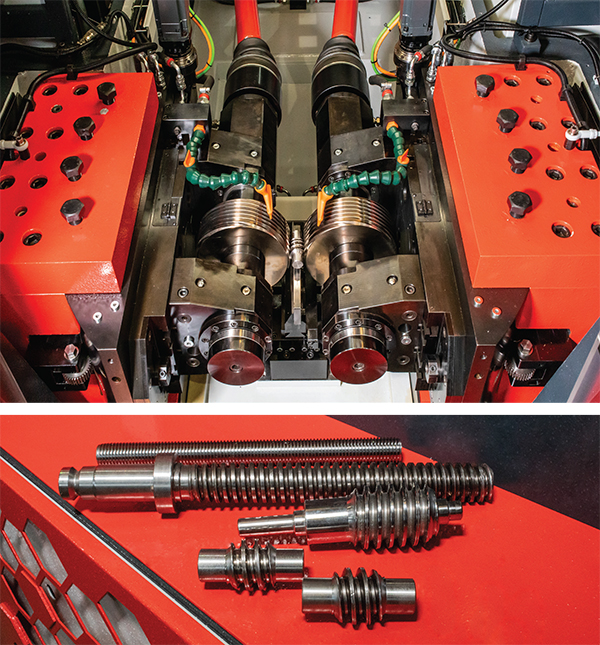

We will present our full optional machine model 2RP30 CNC EVO with a brand-new eye-catching restyling of the frame in the next coming exhibitions in the Europe. This is two moving slide thread rolling machine, the most suitable for the use of automations and feeding devices respect to single moving slide machines. The machine is equipped with:

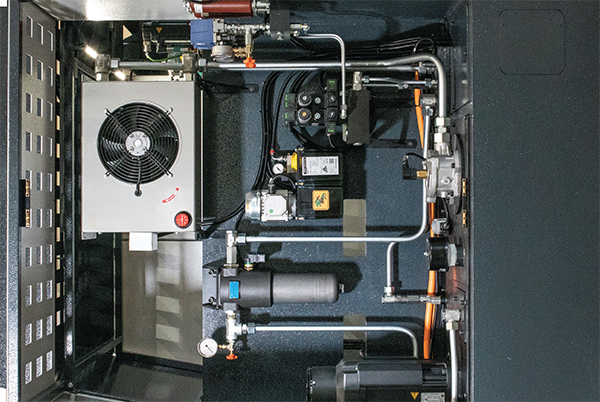

Energy Saving hydraulic unit

The new low consumption equipment has been developed to grant a very important reduction of energy consumption and better functioning in comparison with the most traditional systems. It is based on a electro hydraulic solution, thanks to the use of servo pump, that is composed by a servomotor with drivers and software dedicated to the applications management. Besides the consumption reduction, the new solution grants better

performances of rolling process and its noisy free. With this solution, Consumption saving is calculated until max 80%.

Automatic swivel angle adjustment;

Automatic swivel angle adjustment;

Each spindle’s head is clamped by a hydraulic device during the rolling process: whenever is needed the adjustment of the angle referring to the right angle of the profile, the operator can easily release the clamping calling the requested angle by the OP of the machine.

This adjustment is made by two servomotors, one for each spindle and it grants a very high accuracy and a very quick set-up time for thru-feed rolling.

CNC control

CNC control manages rolling process on highly accurate and precise jobs. Synchronism between two or three slides is perfect. Precision on all axis is under micron meter and seconds of degree.

Newly developed taper setting, visualized on Operator panel;

Effectiveness is never enough, there is need to be more efficient. Easy taper setting is developed with external spur gear to make this setting easily also by watching angle’s movement on operator panel. Thanks to all these qualities, machine is strongly recommended for rolling of ball screw, worm gears, spure gears, highly accurate rolling profiles etc.