WIRE: Hatebur celebrates 90 years of history and presents innovations

-At the WIRE trade show in Düsseldorf, the Swiss technology leader Hatebur showcases its high-tech solutions. Visitors will also be able to gaze at a brand-new Carlo Salvi machine at the Hatebur Booth 16C58 in Hall 16.

-At the WIRE trade show in Düsseldorf, the Swiss technology leader Hatebur showcases its high-tech solutions. Visitors will also be able to gaze at a brand-new Carlo Salvi machine at the Hatebur Booth 16C58 in Hall 16.

-Besides innovations and product novelties, Hatebur and Carlo Salvi will highlight their unique tradition:

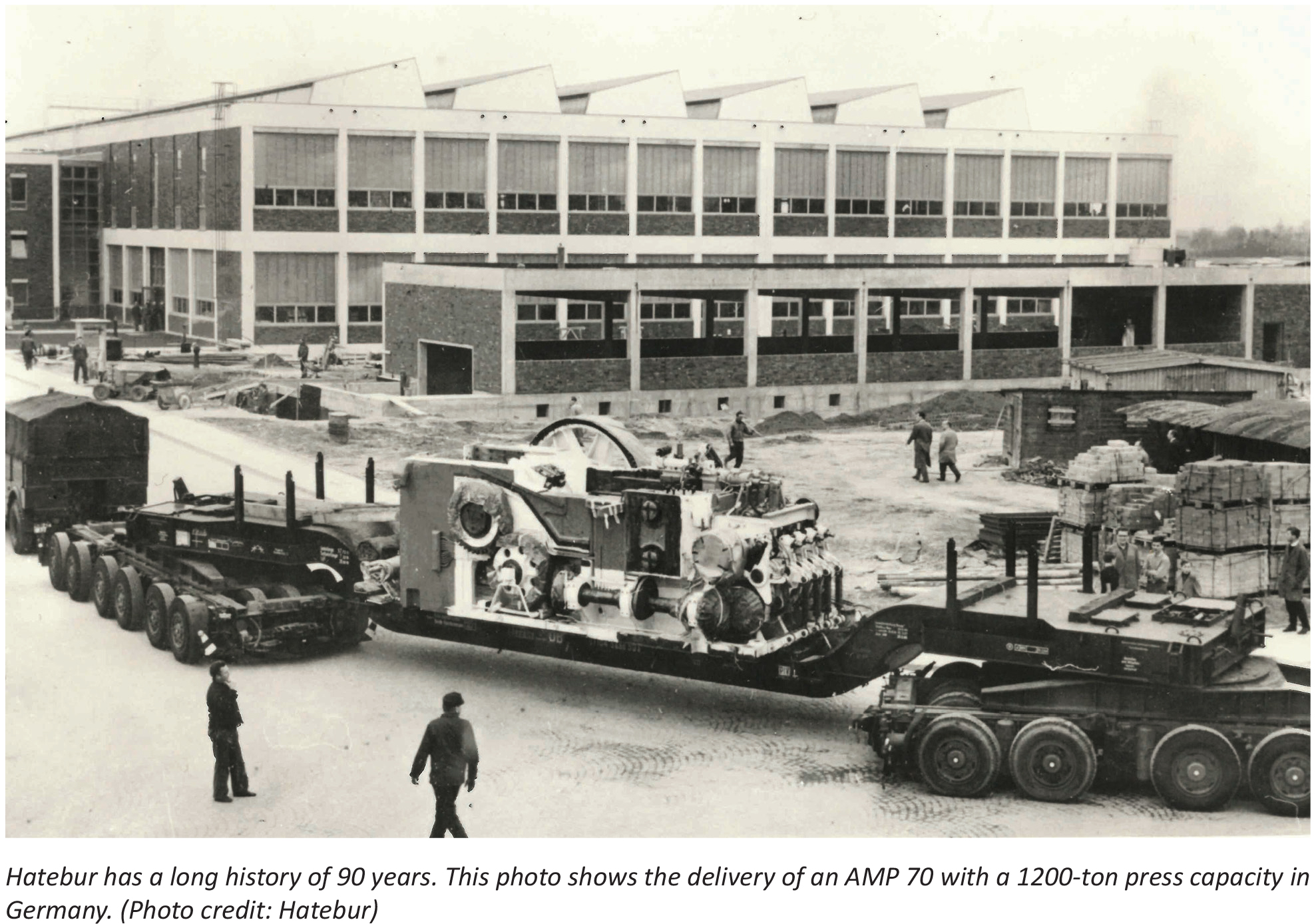

In 2020, Hatebur celebrates its 90-year anniversary. Carlo Salvi, the second brand within the Hatebur company, celebrated 80 years of history in 2019!

-Hatebur will present four key group technologies: servo transfer unit, servo-electric wire feed, servo direct drive and Hatebur Connect.

Reinach, Switzerland (February XX, 2020) – At the WIRE trade show in Düsseldorf from March 30 to April 3, the Swiss metal forming expert Hatebur will celebrate its unique history of 90 years. And because this history is full of technological breakthroughs and innovations, it is only fitting that the company showcases some of its state-of-the-art technologies at its booth (Hall 16, Booth 16C58). Hatebur CEO Thomas Christoffel: “We will focus on four big technology topics: Servo transfer unit, servoelectric linear wire feed, servo direct drive and Hatebur Connect.”

New Carlo Salvi machine

A special highlight for WIRE visitors will be the world debut of a new Carlo Salvi machine concept at the Hatebur booth. Carlo Salvi, the second brand within the Hatebur company, celebrated its 80-year anniversary last year. The merger of Hatebur and Carlo Salvi in 2016 did not only bring together the skills, knowledge and innovative power of two leading companies in the cold and hot forming sectors – it also united two companies that both have an eventful history and rich tradition.

Technology focus

Technology focus

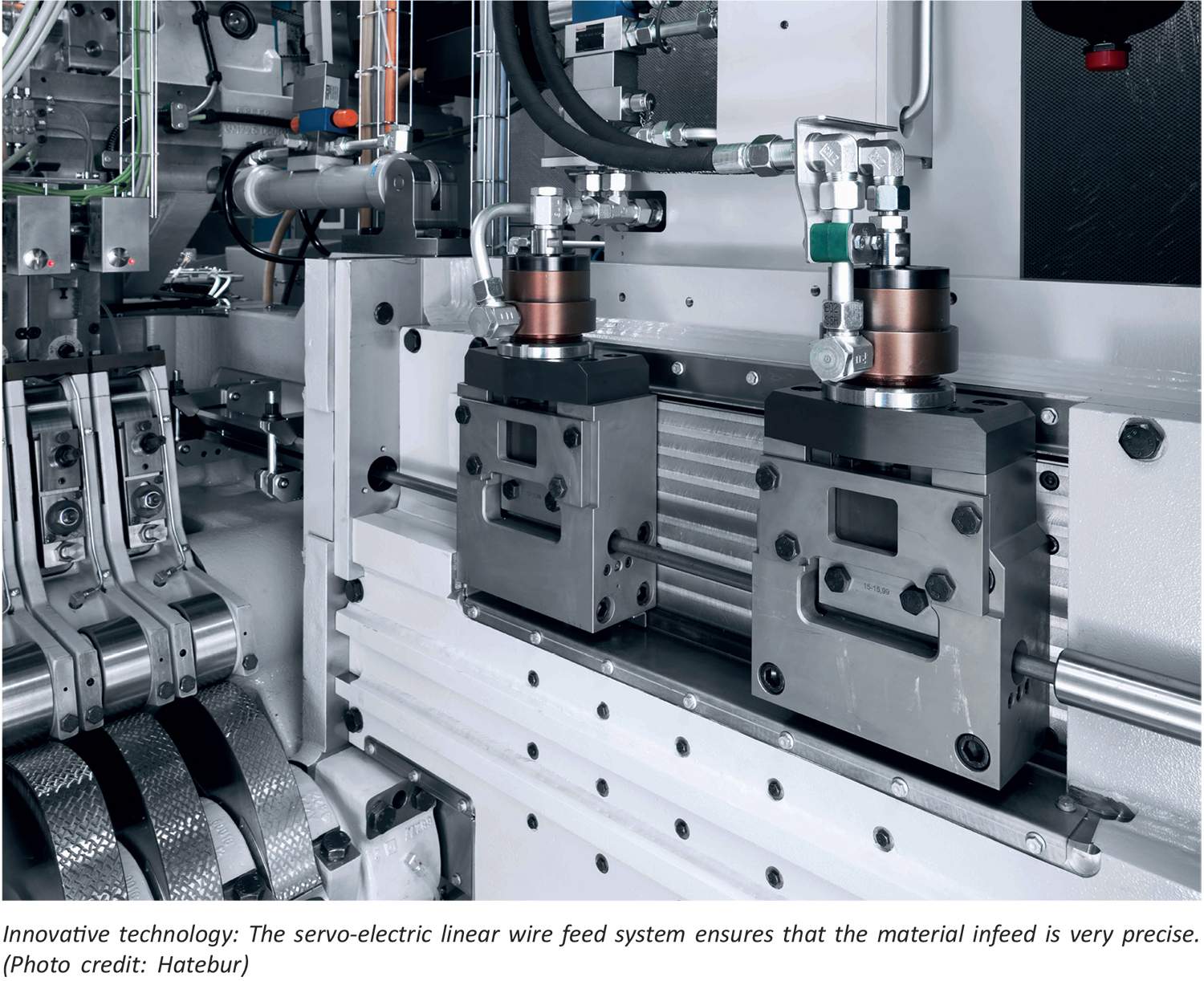

Additionally to witnessing the machine in full production, visitors at the Hatebur booth will be able to learn about some of Hatebur’s outstanding technologies. A servoelectric driven transfer unit will be displayed. Besides the transfer-unit itself, each of the grippers is also driven by a servo motor and can be individually adjusted for opening and closing, bringing enormous advantages when it comes to changeover times. The servo-electric linear wire feed system ensures that the material infeed is very precise with a volume variation of less than 0.3%. The linear indeed requires no wire stop, which eliminates the occurrence of contact marks. Changeover is quick, maintenance is easy. The servo direct drive allows the control of the movement of the press ram detached from the transfer unit and the extreme versatility of the die and punch ejectors, offering new fields of applications. With Hatebur Connect, the company is well equipped for the future. “All the relevant systems within the machines are connected and can communicate, which offers new opportunities for the analysis, data collection, machine status monitoring, preventive maintenance and the overall optimization of productivity”, explains Mr. Christoffel.

A history of innovation

A history of innovation

Throughout their long histories, both Hatebur and Carlo Salvi have always been pushing for innovation. Both companies have achieved numerous technological breakthroughs. The Hatebur history started with the invention of the revolutionary turret-type forging press in 1930. In 1950, Hatebur pioneered the world’s first fully automatic three-die progressive header with horizontal tool layout. Another milestone came in 1956, when the Hatebur engineers were able to make the hot formers, previously only used for nuts, fit for manufacturing ball bearing races. The first AMP 30 hot former marked the start of a global triumph. Numerous new technologies and machines were introduced thereafter and until today. Carlo Salvi, founded in 1939, started the production of flat die thread rollers in the 1940s. In 1952, the company introduced its first single die double blow header, a true breakthrough innovation because of its speed of 400 parts per minute. In the 1970s, Carlo Salvi produced a line of headers for the production of semi tubular or fully tubular parts, boosting the productivity of its customers. The first single-die double-blow header equipped with linear wire feed, quick change kit and electronic interface was launched in 1999. Until today, innovation, research and development are integral parts of the Carlo Salvi DNA.

About Hatebur:

Hatebur is synonymous with first-class hot and cold massive forming, exceptional customer service and premium-quality process engineering. Thanks to the integration of Carlo Salvi, Hatebur customers around the world benefit from a wide range of innovative solutions. This traditional company, founded in 1930, employs an international network of fully owned subsidiaries and sales partners to guarantee high-quality products and services that are never far away from its customers. After an in-depth consultation and design process, Hatebur offers a machining solution for producing high volumes of precision metal parts that meets the customer’s needs and requirements perfectly. Whether for the automotive, rolling bearing, aviation or fastener industry, we create solutions that offer maximum performance and efficiency in accordance with our guiding principle: Our performance. Your advantage.

Media Contact:

Bernhard Hagen

Hagen PR

www.hagenpr.com