LogOil is the innovative tool to detect leaks and spills in tanker oil transportation, manage the deliveries and secure the supply chain at a competitive price. LogOil is one of a kind packaged solution, which unites several technologies to deliver the ultimate system for smart and secure fuel transportation. LogOil will bring you to the highest level of theft and fraud prevention, sturdiest accuracy and automation in oil delivery. Our sophisticated software system constantly logs, analyses and reports all product and tanker parameters, received from the high end magnetostrictive probes and sensors on the tanks.

LogOil is the innovative tool to detect leaks and spills in tanker oil transportation, manage the deliveries and secure the supply chain at a competitive price. LogOil is one of a kind packaged solution, which unites several technologies to deliver the ultimate system for smart and secure fuel transportation. LogOil will bring you to the highest level of theft and fraud prevention, sturdiest accuracy and automation in oil delivery. Our sophisticated software system constantly logs, analyses and reports all product and tanker parameters, received from the high end magnetostrictive probes and sensors on the tanks.

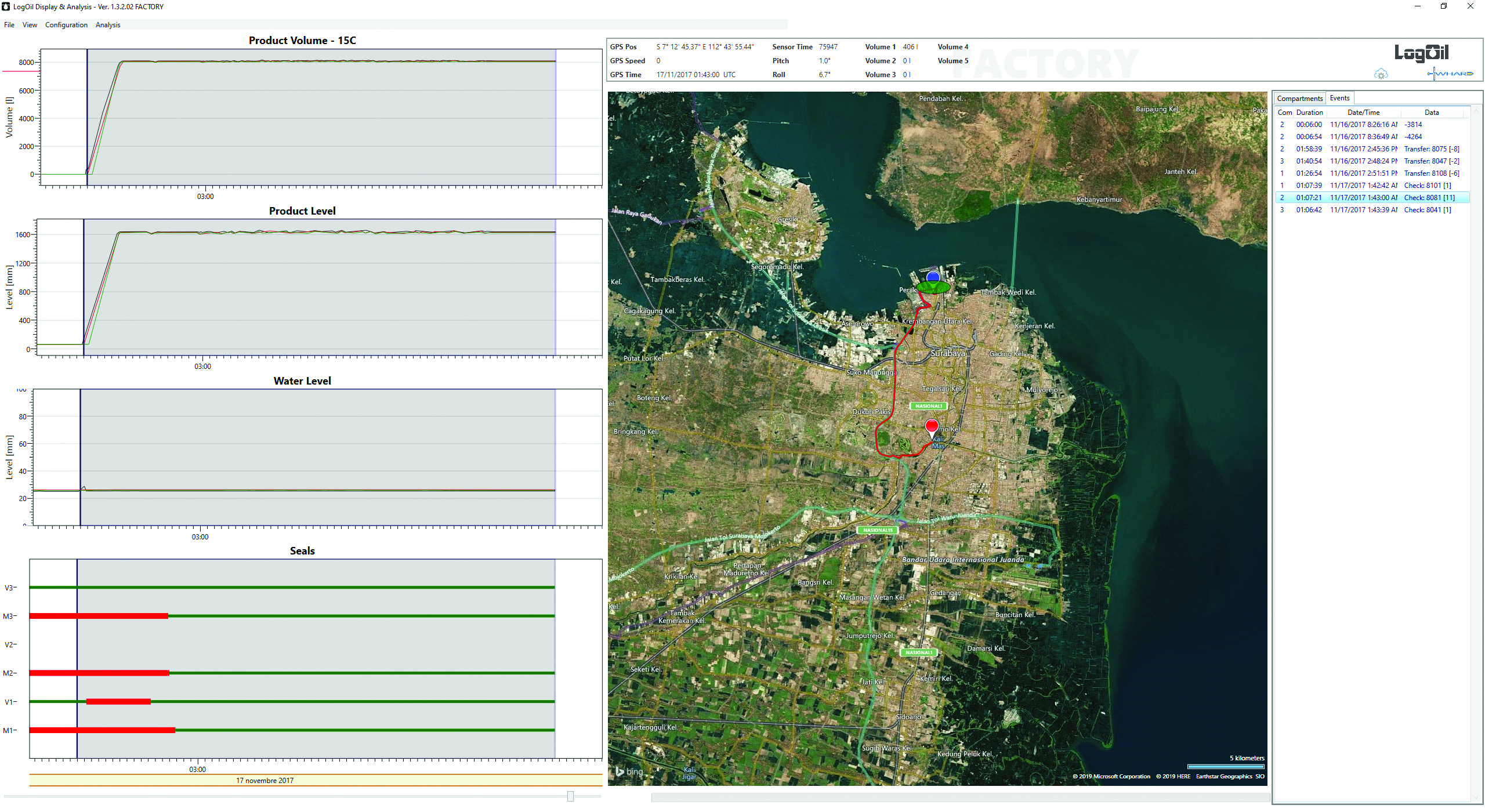

Thanks to the algorithms taking into account all internal and external factors and variables, the system identifies and evaluates loads, unloads and leaks from the tanker track with 99.8% accuracy. This means that regardless of the external factors, the petrol fleet management team can account for all fuel products, in all tanker trucks with the accuracy of +/-2 liters per metric ton. Thanks to LogOil system it is always possible to have a detailed record of when, where and what happened to your tanker truck and fuel products during transportation, leaks-on-the-move and overturns included. Fluid transportation security is just one thing that LogOil brings to you, but our technology enables several features, described below.

DELIVERY MANAGEMENT

With its unique features and the possibility of interfacing the system to the Company’s ERP, LogOil is capable to provide a complete and automated management of the product delivery process. Providing quantification at standard temperature of loads and unloads at their locations the system, both the sender and the receiver are notified about possible altered deliveries, pointing out unplanned loads/unloads, potential adulteration, higher/lower quantities.

SUPPLY CHAIN AND PRODUCT INTEGRITY

By securing tanker truck transportation, LogOil fills the gap in the oil delivery chain control. LogOil can be applied to static containers or can be interfaced to systems already installed, enabling the full and automated monitoring of the entire supply chain, providing adulteration-free products delivery and environmentally secure logistics.

REAL-TIME PRODUCT DELIVERY MONITORING

If your business model involves the transportation of petrol products, CNG, LPG, dangerous and volatile chemical gasses and liquids, or any other heavily regulated gaseous or liquid substances, LogOil will empower you to over-comply with the regulatory requirements and, at the same time, will give you real-time product delivery monitoring.

WHO NEEDS LOGOIL?

WHO NEEDS LOGOIL?

Oil & Gas: from big companies transporting monitored liquids/chemicals, oil/petrol depots, petrol products dealers, petrol products transportation companies, to the operators of small civil gas tanks distributing products in urban environments. There are several versions of LogOil, for each intended use. Cleanliness and Environmental Prevention: companies, which specialize in cleaning, draining and disposal of pollutants.

Military Use and Special Civil Cases: transport of dangerous liquids and liquid radioactive materials, unauthorized dumps location.

SYSTEM SPECS

HARDWARE

The hardware part is composed by a collection of sensors for the acquisition of various parameters, a data logger and a ground station (LogOil Station).

-Up to 5 compartments per tanker, customizations available

-Data storage and wireless communication is encrypted end-to-end

-LogOil Station automates data recovery and transmission to server/cloud

-LogOil Manager mobile application allows for manual data download and system configuration

-Electronic hardware is self-contained and not accessible for tampering minimization

-Assembly may be protected with both electronic and mechanical seals

-No batteries required

-Start up time < 1 sec

-Voluntary power supply disconnections are detected and reported

-Real-time alarm transmission (tanker truck overturn included) available on request

-Internal memory holds from 4 days up to 15 days of data

-Support for RS232, RS485, CAN Bus, Digital inputs, 802.15.4 devices (sensors or seals)

SOFTWARE

The software part combines multiple data from the hardware computing and delivering information to the

customer or to an ERP system.

-Standalone analysis application to automatically detect relevant events (loads, unloads, leaks-on-the-move, etc.)

-Cloud based analysis software for cost reduction, better scalability and improved data security

-Customized ERP integration on request