Author: Paolo Muscetta

Development & Technical Assistance

Industrial Lubricant Manager

Lubricants Business Unit

Eni Refining & Marketing

Diathermic fluids are used as means for transferring thermal energy produced in a burner (source) to one or more users in a wide variety of industrial sectors such as chemical plants, textiles, food processing, marine applications, wood processing, production of plastics and rubbers, metal processing, paper, construction materials, electric radiators or in all those processes operating in a wide range of temperatures. The transfer of thermal is performed in a safer and efficient way through a diathermic fluid rather than by the use of steam, electricity or through direct flame contact, that is why all industrial sectors are mainly oriented towards heat transmission systems of indirect type. The most common diathermic fluid, less expensive and with high efficiency in heat transmission is water. Unfortunately, water has a very limited range of operative temperatures, indeed, in nonpressurized systems, the working temperature must be within the range 0 ° C (freezing point) and 100 ° C (boiling temperature at atmospheric pressure). In applications where the temperature range is more extended, other fluids have to be considered. In particular, for cooling system applications requiring temperatures lower than the water freezing point, the halogenated hydrocarbons, ammonia or mixtures of water and glycols are used as chilling fluids. In case of temperature range from -10 ° C to 410 ° C, the most suitable products are synthetic “aromatics”, they consist of benzene-based structures and include the diphenyl oxide/biphenyl fluids, the diphenylenthanes, dibenzyltoluenes, and terphenyls. The main advantage of the synthetics over mineral oils is that they guarantee safe operation with temperatures up to 400°C, but they have a very high cost, around three times higher than mineral oil. In the most common applications with operating temperature up to 340 °C, mineral oils are general used provided the system is pressurised with a nitrogen blanket. The choice of using a mineral oil as a thermal energy carrier arises from the need to have a fluid at relatively low cost with good performance that does not require a complex plant layout. The mineral heat transfer fluids are generally suitable for operating temperature from -18 ° C to 340 ° C (film temperature) at atmospheric or higher pressures. In these operating conditions the oil remains in the liquid phase and this allows to avoid the expensive pressurised system necessary to control the vapour, moreover the mineral oil guarantees a high thermal transmission coefficient (from 300 to 1700 W / m2 K in forced conduction regime) that allows to downsize the exchange surface obtaining a cost reduction. Moreover, a heat transfer mineral oil formulated with highly refined base stock shows a good thermal stability, not corrosive properties, allowing the lubrication of the mechanical parts.

Mineral heat transfer fluid: formulation & Monitoring

In the formulation phase of a new heat transfer fluid, the choice of the mineral base oil is crucial to obtain a high performance product, during its lifetime the oil is subjected to a severe thermo-oxidative stress, so the target is to formulate a product having a long lifetime avoiding rapid aging; for this purpose, due to their very low olefin content, highly paraffinic base oils are generally preferred, whilst concerning additives, antioxidants and metal deactivators are typically preferred. A big impact on heat transfer lifetime is given by the operative conditions such as maximum operating temperatures, type of flow (laminar or turbulent) and plant layout (open or closed). For example, the presence of de-aeration/ expansion vessel blanketed with inert gas ensures the removal of entrained air, vapour and light fractions prolonging the lifetime of the oil. Eni can count on its own R&D activities and field experience for more than 30 years that has allowed to keep its traditional product line (Eni Alaria) always updated with current technological developments.

Eni can timely provide technical assistance to support the customer:

-choosing the proper oil according to layout plant and working temperatures;

-backing up in plant design providing the key features related to the heat transfer (density, viscosity, specific heat, thermal conductivity, Prandtl number);

-developing the guideline to manage the oil charge in the correct way (sampling scheduling, oil parameters, threshold limits);

-suggesting the right action related to oil charge status (top up, replacing, filtering, flushing).

The support in the charge monitoring is important not only to ensure the best performance, such as the control of impurities, the presence of water, the formation of carbon residue, but even more fundamental for the safety of the plant, the fire and explosion hazard that could occur if the charge monitoring is not carried out in correct way. When heat transfer fluids degrade, they form a mixture of high-boiling polymeric compounds “high boilers” and volatile low-boiling compounds “low boilers” as showed in typical degradation reaction: The presence of high boilers has an autocatalytic effect on degradation and it determines an increase of viscosity and the formation of carbon residues in presence of oxygen at higher temperature as for the reaction:

The presence of high boilers has an autocatalytic effect on degradation and it determines an increase of viscosity and the formation of carbon residues in presence of oxygen at higher temperature as for the reaction: The presence of low boilers can lead to a vapour lock if the system is not properly vented and in addition it determines a strong decrease of flash point P.M., autoignition temperature while the flash point C.O.C is less sensitive to the presence of low boilers.Moreover, the low boilers determine on the distillation curve of the oil a lowering of the initial boiling point and an increase of the final point. During the lifetime of the oil charge, a monitoring of all these parameters (flash point, autoignition point, distillation curve) is crucial to predict the oil charge service life and the actions to be taken in order to assure the safety conditions and the best performance of the product. The presence of air reduces further the oil lifetime, the air (oxygen) through the radical path leads to formation of polymeric compound (peroxide) that have a big impact on oil characteristics: increasing of viscosity and acidity (TAN), lowering Flash point and auto-ignition point and forming the carbon residues. The oxidation reaction is catalysed by presence of metals in the oil for example: iron and copper.

The presence of low boilers can lead to a vapour lock if the system is not properly vented and in addition it determines a strong decrease of flash point P.M., autoignition temperature while the flash point C.O.C is less sensitive to the presence of low boilers.Moreover, the low boilers determine on the distillation curve of the oil a lowering of the initial boiling point and an increase of the final point. During the lifetime of the oil charge, a monitoring of all these parameters (flash point, autoignition point, distillation curve) is crucial to predict the oil charge service life and the actions to be taken in order to assure the safety conditions and the best performance of the product. The presence of air reduces further the oil lifetime, the air (oxygen) through the radical path leads to formation of polymeric compound (peroxide) that have a big impact on oil characteristics: increasing of viscosity and acidity (TAN), lowering Flash point and auto-ignition point and forming the carbon residues. The oxidation reaction is catalysed by presence of metals in the oil for example: iron and copper.

Eni heat transfer oil: Eni Alaria product line

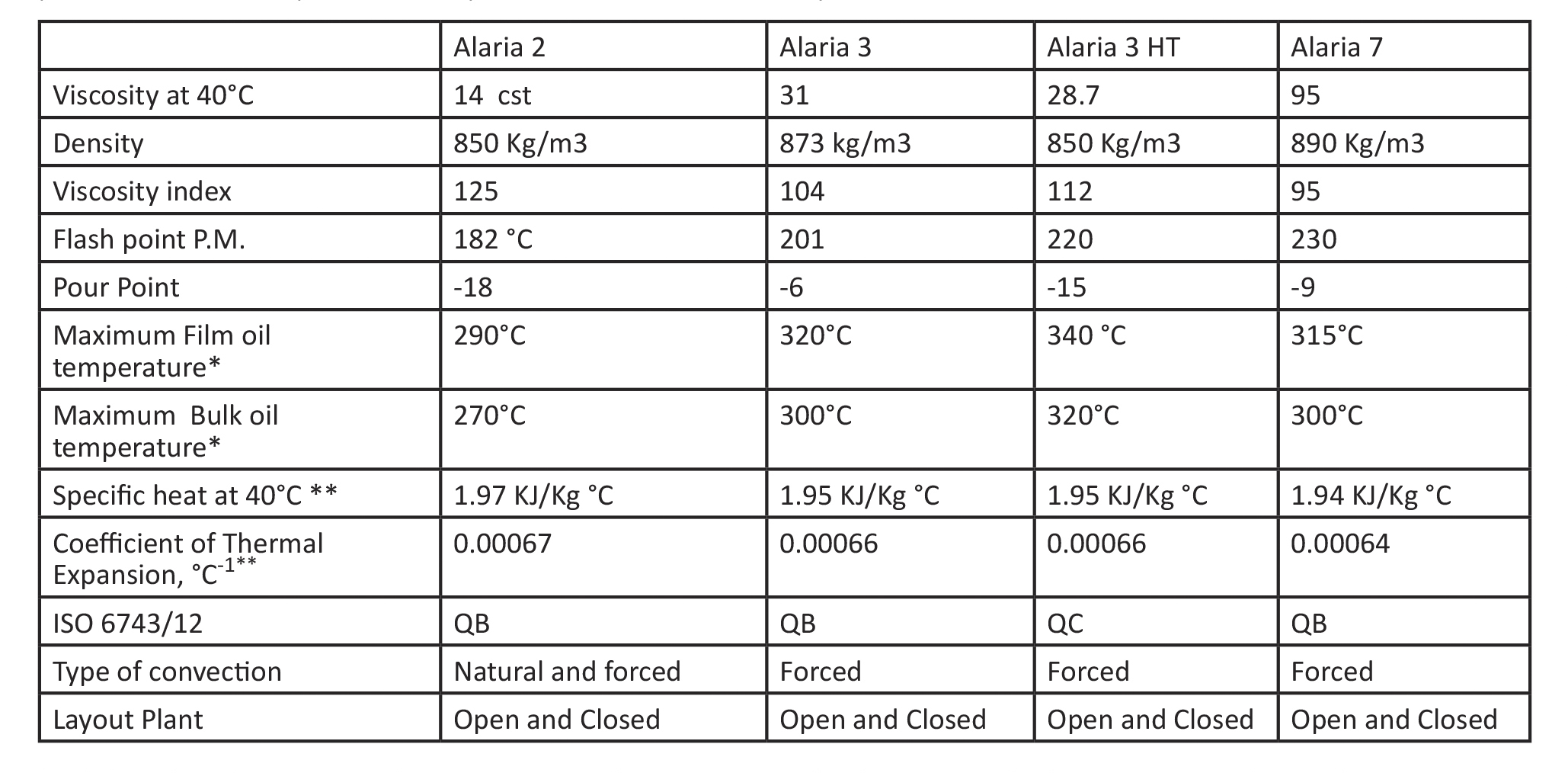

Eni Alaria line is characterized by an excellent oxidative stability and thermal cracking resistance based on highly refined base oils. The resistance to thermal cracking contributes to reduce the formation of sludge and deposit, prolonging the oil lifetime and extending the maintenance intervals. The line, consisting in four products with different viscosities and characteristics, has been developed to meet the requirements of the main applications. In order to choose the right oil, it is mandatory to know the plant working temperatures (the maximum film temperature, the maximum bulk temperature) and the type of plant (open or closed systems). *Valid in Closed systems, in the open system the presence of air affects the thermal stability of the product, the maximum bulk oil temperature is 180° C for Alaria 2, Alaria 3 and Alaria 3 HT and 250°C for Alaria 7

*Valid in Closed systems, in the open system the presence of air affects the thermal stability of the product, the maximum bulk oil temperature is 180° C for Alaria 2, Alaria 3 and Alaria 3 HT and 250°C for Alaria 7

**Estimated values.

Open system is a system where the oil comes in contact with air at some point of the system, it is important to mention that in an open system the fluid comes in contact with air in some point of the heating circuit and if this happens at high temperature the oxidation stresses on the fluid could be particularly significant; conversely, if the temperature is low (less than 80 °C) the oxidation process have a limited importance, so that the application can be considered of mild severity and similar to a closed system. Closed system is a system where typically there is an inert gas (nitrogen) between any point of contact of the oil to the atmosphere. In this system there is no consistent presence of oxygen.