We design custom-made, unique, selected software solutions

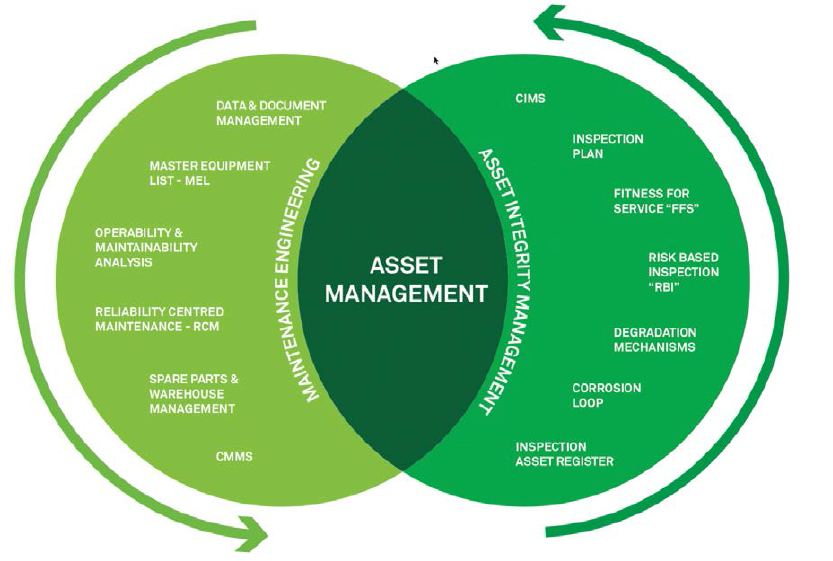

RAMCUBE is a Company specialized in the development and application of Asset Management (Maintenance Engineering and Asset Integrity). In the modern vision of the Company organization, Asset Management is a transversal discipline responsible for the design, control and continuous improvement of the Maintenance and

Inspection System. In particular, it makes it possible to supervise maintenance and inspection activities; define

maintenance and inspection policies; manage spare parts; promote standardization; define workload and required skills; manage KPI; guarantee the availability of the plants and cost reduction; ensure compliance with local laws and regulations; prepare and promote the use of adequate operational support tools.

RAMCUBE key pillars:

Survey and continuous improvement:

We believe that in order to significantly enhance the efficiency of the system and to preserve its duration, it is necessary to apply a simple rule: “listen”. For this reason, a Survey Check List has been developed taking into consideration all past experience collected about several Projects.

Plant analysis and implementation of proposals:

RAMCUBE is able to provide a range of support services: training, collection and loading of plant data, creation of maintenance/inspection lists, spare parts cards,

spare parts interchangeability report, Manufacturers and Vendors follow-up, maintenance and inspection policies, customized maintenance and inspection plans, customization of approved work flows, management of workloads with consequent rationalization of resources, drafting and evaluation of KPIs.

Implementation of main maintenance and inspection methodologies:

RAMCUBE through its specialists is able to propose specific studies: FMECA (Failure Mode, Effects, and Criticality

Analysis), RCM (Reliability Centred Maintenance), RAM (Reliability, Availability and Maintainability) using MAROS software®️ , OMA (Operability and Maintainability), Spare Parts Optimization Analysis, Material Coding, RBI (Risk Based Inspection).

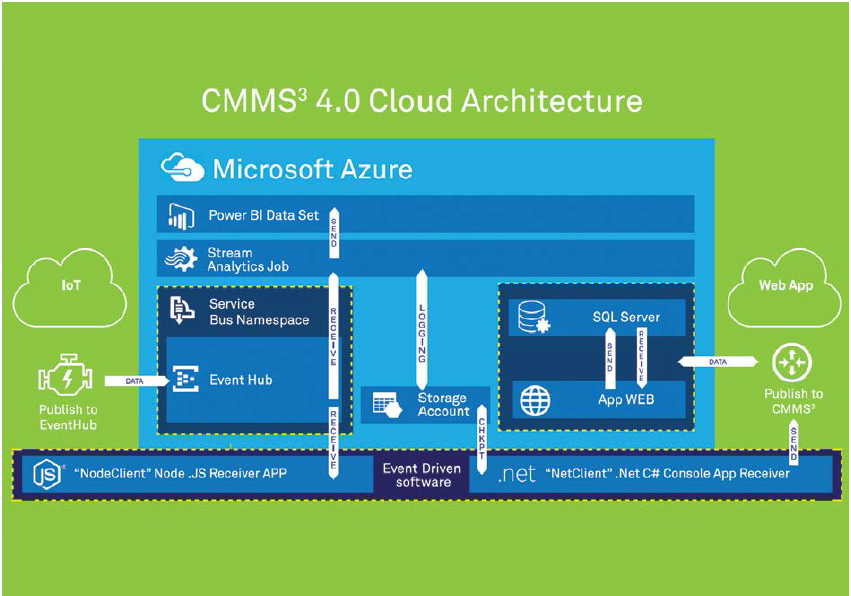

CMMS Implementation:

The CMMS³ “Maintenance Management System” is the IT tool to support maintenance and inspection services. The

proprietary software, which has important references, is economically very competitive with the aim to facilitate

the development of the Operation activities in terms of Maintenance and Inspection. CMMS3 is now available on the Microsoft Azure TM®️ platform for easy cloud implementation.