Ferranti, Special solutions and strong partnerships

With this strategy in mind, Ferranti Milano has managed to reach many sectors in very short time, providing a wide range of components that have been selected to meet the most demanding technical requirements.

Founded in 2007 from the experience gained in the field of ball bearings, positioning machines and transmission belts, Ferranti is a young and dynamic reality in the trade and production of technical components. The company’s mission is to offer high-tech and highquality solutions, developing a great selection of products, working with top brands and having competitive prices. Thanks to its strong partnerships with important manufacturing companies, each product made by Ferranti is carefully produced in order to offer the best technical and commercial solution for its customers’ needs. “Throughout our history, we have developed great expertise in the study and implementation of products for specific applications. This is what we want to focus on in the future.”

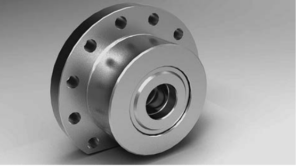

One of the products Ferranti stands out for is a particular type of bearing, which is used to isolate electric currents, also known as eddy currents, that generate in electric motors. These currents can cause untimely bearing failure, which therefore needs to be replaced with high maintenance costs. “These components are manufactured using the most advanced technologies, such as the use of plasma, which allows eddy currents to be isolated up to 250V or up to 1000V for the highperformance model. Our company is the only company on the market capable of insulating ball bearings, cylindrical roller bearings, needle roller bearings and tapered roller bearings.”

Ferranti also specializes in machine tools and develops ball screws supports. Flange or square bearings are available, with embodiment for pairs or two pairs of precision bearings. These supports guarantee maximum rigidity and precision of the screw axis, for sliding with a margin of error close to the micron. Moreover, thanks to its great know-how, Ferranti also produces customized products according to the customer’s requested design

Since Ferranti has a very wide range of rolling bearings in stock, both ball bearings and roller bearings (with holes up to 800mm in diameter), particular attention is given to the following sectors: Power, Oil&Gas, Naval, Steel and heavy industry. Spherical roller bearings, tapered roller bearings, cylindrical roller bearings with 4 or 5 rows of cylindrical rollers (multiroll), radial ball bearings and axial ball bearings – these are just some of the products available in stock. Moreover, most of the roller bearings are made with solid brass cages to support higher loads – a feature that is not easy to find on the market.

Thanks to the company’s facilities and experience, Ferranti is able to produce special bearings for any customers’ specific need or to reproduce special types of items that are no longer available on the market. The company can produce many different customizations to suit its customers on the basis of the following parameters: geometry of the raceways of rolling elements or ferrules; balls in different materials (e.g. ceramic) and precision; bearing rings with different diameters and thicknesses; bearing internal clearance.

Ferranti is currently setting up a metrology room that will allow the company to verify the characteristics of the components used by its customers and, in case of problems, to suggest alternative solutions. Ferranti’s goal in the future is to organize this area in order to be able to give specific feedback on specific application cases.