Pipe-shop Automation with full Software Support

Pipes and tubes are a critical component for many structures and vehicles, and are therefore indispensable to modern society, leading to increased demand on pipe-shops and spool fabricators.

But the workflow inside a pipe-shop needs to be carefully planned and controlled, because it is vulnerable to a lot of factors that can affect output and productivity. Some of these factors, such as supply-chain management are external to actual fabrication, others, such as bottlenecks caused by badly planned logistics inside the shop are not.

Different shops have different requirements, so it is important to know the type of spools to be fabricated, as well as the materials and dimensions. That is why simply looking at each machine or process as a closed system can lead to significant problems, as transport ways may be too long, or capacities may not match. Non-standard fabrication requirements cannot be met with a standardized solution.

The company 3R solutions from Germany is an expert in the field of pipe-shop automation and optimization. With more than 40 years of experience in planning and implementing pipeshop projects all over the world, they have the expertise to help customers from diverse fields to identify the best way to build and operate their specific shop.

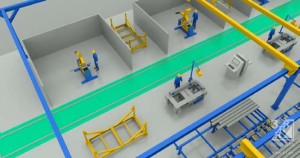

One of the keys to 3R’s philosophy is a streamlined and optimized flow of material. Instead of using overhead cranes and manual transport, 3R’s pipe shops include automated transport systems, using roller and plate-belt conveyors as well as buffer tables. This way costly idle times and doublehandling are avoided, and all machines and operators can work continuously, without having to wait for material to be delivered to their stations. On the machine side 3R solutions work with many renowned machine manufacturers, and are therefore able to select the best possible machines for each task. These machines are integrated into the transport system and highly automated, so the operator generally only has to supervise the processes, interacting only if necessary and in minor ways.

Another key component of 3R’s process is the internally developed software suite, which can organie and control the entire process flow. In addition it is used to involve warehousing and engineering departments, instead of only looking at the fabrication process itself. Thus it is possible to streamline the preparation of drawings and data, the transfer of information to the machines, and the real-time tracking of fabrication processes. Ideally a supervisor or production engineer will at all times be able to access up-to-date status information for any spool currently in his workshop.

It is by combining this use of software with smart and streamlined workflow processes, that customers of 3R solutions have managed to achieve significant savings and favorable returns on investment over the past years.