BM Group -Polytec Robotics-

TECHNOLOGIES 4.0: A COMPETITIVE EDGE FOR TUBE&PIPE PRODUCERS

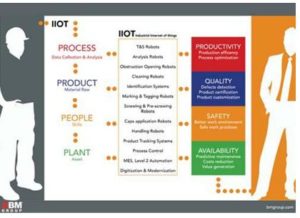

After car assembly plants, technology is arriving to Tube&Pipe Mills, as important key to increase operator’s safety and to improve process efficiency and product’s quality. Today reliable systems can replace human operator from hazardous areas and are able to standardize and automatize repetitive tasks as marking or tagging operations. Advanced machine vision systems allow to collect and manage data and report useful information towards quality standard and productivity.

The italian Polytec Robotics, business unit of BM S.p.A. is a story of success begun in 2012 when BM Group invested in a new company, focused in the production of highly technological robotic cells for the steel market. The deep knowledge of the steelmaking process acquired in the steel sector as supplier of automation systems, together with a constant investment in R&D have been the keys to early understand the increasing new needs of steelmakers, safety, productivity and quality.

In few years, Polytec has developed a range of more than 15 robotic cells that integrate the steelmaking process, from the furnace to the finishing mill (long&flat

- tube&pipe). Each solution is manufactured on customer needs, tested in Polytec workshop and rapidly installed in new steel plants, as well as in existing ones. Advanced machine vision systems integrate the robotic cell and allow to collect datas and verify product quality and process performances.The Motto “From operator to supervisor” explains clearly how the role of human operator changes: operators now supervise the activities from the pulpit of control and therefore work environment and work conditions positively improve.

The upgrade to 4.0 passes through the communication between robotics and process automation. Reliability is what Polytec Robotics can offer, from feasibility to assistance and education.

THE MILESTONE

POLYTEC: WORLD LEADER IN ROBOTIC SOLUTIONS FOR STEEL INDUSTRY

In 2017 Polytec Robotics has reached quota 100 robotic solutions intalled in steelmaking plants all over the world becoming World Leader in this branch

JUST FOR A WHILE

CAN YOU IMAGINE A STEEL MILL 4.0?

From central pulpit, the operator manages the automatic scrap yard crane for bucket loading and bucket charging into EAF and supervises the activities of the full automatic robotic system for the measurement and samples picking and for the 360° internal view of the furnace. On Continuous Casting, the multitool robotic solution for ccm, is positioned next to the ladle with its dispenser storage equipped with a ladle shroud positioning tool, a ladle shroud cleaning one (oxygen shower), T&S lance for sample and measurement and a powder distribution. Operator controls the whole cycle via CCTV. After casting, an advanced vision system check each billet arriving from roller table in order to identify possible geometric defects and a full automatic tagging machines applicates the customized tags on the billet. Depending on the type of finished product outgoing, if bundle tubes or wire rods or flat prodcuts, there’re is a specific robotic cells for the last tags application. The traceability of the complete process is possible thanks to a tracking system that collect, analyze and manages all the production’s data. That’s what we do.

BM Group: Integrated Solutions Provider.

NEW!

PolySHAPE: THE ROBOTIC CELL FOR DIMENSIONAL CONTROL OF BILLETS, SLABS, B L O O M S

The new robotic system developed by Polytec Robotics is able to scan with a calibrated tool installed on a Robot a billet (square or round), H-beam con dimensional control associated with temperature Robot with single

calibrated head containing 3D Laser Scanner, Thermal Imaging Camera

- The system is able to scan the product

in a fix position up to a temperature of 850 °C

- Management of different types of products available thanks to the recipes in the software

- Measurement accuracy for H Beam up

to + -2 mm, for billets + -1mm

- Dimensional control for precise

measurements, diagonal calculation and area

- Linearization of acquisitions with thermal imaging cameras in order to dynamically

manage cooling curves and change dimensional m o r p h o l o g y

- Saving on the local and remote database of the information for interfacing with MES systems

- User friendly interface

- Simple installation PLUG&PLAY