The Promise of Monitoring Live-Tooling Performance

Sensor technology on live-tooling units could not only prove valuable for predictive maintenance but also overall production monitoring and improvement for a range of machine tool brands .

Many machine tool builders are building intelligence into their new machining center designs. During the design process, they have direct control over where sensors might be located, what types of process variables they want to measure, how sensor data is communicated to the machine’s CNC and apps, and so on.

Manufacturers of machine tool accessories are similarly working to enable their largely mechanical products to provide operational data to optimize their performance and assist in scheduling preventive maintenance routines . However, their challenge is creating products that can integrate and communicate with a range of machine tool brands while offering plug-and- play installation for shops that are adopting data-driven machining practices .

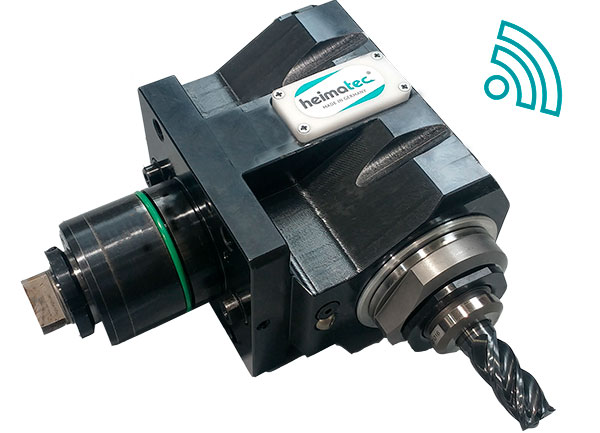

heimatec, manufacturer of precision tools such as live tooling units for CNC turning centers, is one ex ample.

The company is currently refining and testing its heimatec .Sensoric digital tool management technology which uses sensors embedded in live tooling units to measure and communicate parameters, including unit rotational speed, temperature and vibration. The goal is to use that data to optimize the performance of already sophisticated machine tools on which perhaps

multiple live tooling units are installed.

Prior to this, it would be up to a machine operator or programmer to determine the proper speeds and feeds for a given live tooling unit. In some cases, the live tooling unit might not be realizing its potential in terms of material removal, tool life and so on. In other cases, the live tooling unit might be pushed beyond its recommended performance rating, which could result in excess heat and premature bearing failure.

Shops will soon be able to use data collected from heimatec live tooling units to understand what is actually happening inside them — to then possibly tweak cutting parameters in the part program to limit heat and vibration while optimizing unit performance.

This intel can also be used to better schedule preventive maintenance or rebuilding of live tooling units, while preventing the possibility that a unit might unex pectedly fail. To enable the sensing system on a live tool unit to supply its sensors with energy independently of the machine tool brand, heimatec has developed an energy harvesting solution that enables the driven tool unit to operate autonomously.

The energy harvesting solution uses the rotational energy of the machine spindle and converts it into electrical energy. At the same time, the sensoring system is equipped with a rechargeable battery and a charging socket to ensure an energy buffer when the live tool unit is not in operation, so that data can still be retrieved.

Data from the live tooling sensors are transmitted wirelessly via Bluetooth Low Energy (BLE) to a monitoring station and can then be evaluated at a machine’s CNC (using a communication protocol such as MTC onnect or OPC Unified Architecture) or to an app on a computer, smartphone or tablet. heimatec is refining how that data is presented to users on those platforms.

The company is also continuing its own tests and plans to send numerous live tooling units to key customers in G ermany for additional testing. Platinum Tooling, which has CNC turning centers in its Prospect Heights, Illinois, facility, will be performing tests as well. High-volume shops in which live tooling units are in the cut quite often are said to likely benefit the most from this technology, although it is also suited to high-mix , low-volume operations .

Originally appeared in Production Machining (productionmachining.com). Copyright 2022, Gardner Business Media, Inc., 6915 Valley Avenue, Cincinnati, Ohio USA.