Innovation and flexibility in secondary packaging

The Company located in Piacenza got a series of orders focused on case packers for an important Spanish company in the “Organic” beverage market.

Technological innovation and productivity are, today more than ever, linked to the operational flexibility of the machines, which must be able to follow the demands of a market that the pandemic has changed in its assets.

Covid-19 has accelerated the entire packaging ecosystem and the main companies have pushed to achieve the settled targets in terms of materials and volumes, with a glance at the new challenges of secondary packaging

aimed at replacing plastic with environmentally sustainable solutions.

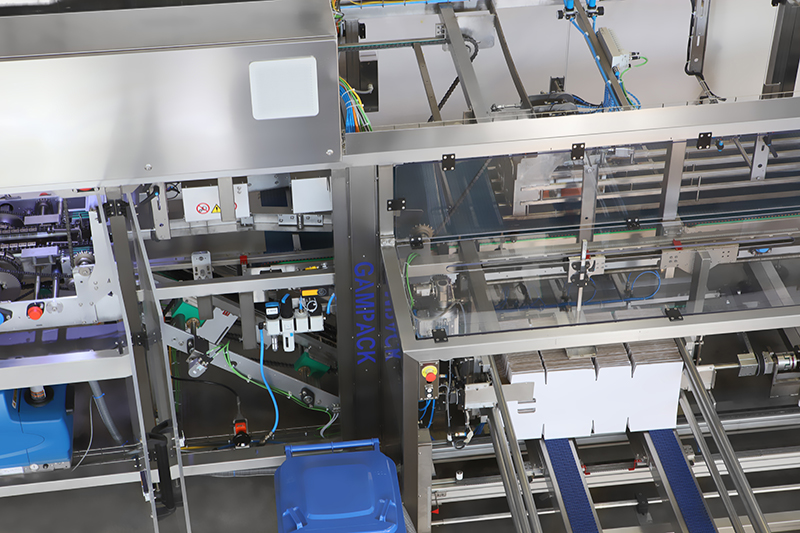

This is precisely the mission of Gampack Group, the Italian leader in secondary packaging. The network was born from the strategic partnership between Gampack and FuturaPack, historic companies located in the

heart of the Emilian Packaging Valley. Gampack stands out internationally in the secondary packaging sector with traditional automated high-speed machines, while FuturaPack is a leader in the design and construction of

end-of-line robotic systems.

Gampack has a series of orders carried out for an important Spanish company producing organic and vegetable drinks, located in the natural park of Montseny (Spain), where pure water, low in sodium and with many

minerals, flows and is used by the Customer for their own organic drinks.

The relationship between the two companies was born in 2007, with the supply of an innovative Wrap-Around case packer with handle applicator integrated into the machine frame, unique on the market and capable of

combining an operator friendly use, energy saving and packaging quality.

Over the years, their relationship of trust has raised, and many packaging machines have been delivered with increasingly customised models.

An example of this settled synergy is Gampack fully flexible cardboard packer operating formats from 2×2, 3×2, 4×3 up to 1⁄4 or 1⁄2 pallet tray, in one single frame, even open to the opportunity of further upgrades according to the evolution of the markets.

From the constant exchange of information between the two companies, innovative options and applications in the machines range have been developed and implemented by Gampack, in a fluent synergy of processes, people and objectives. In 2020 the last model of Wrap-Around packaging machine with integrated handle applicator was delivered to the Customer, in a completely flexible version moreover equipped with a fully automatic format change system (approx. 3 minutes) from Hmi, where the operator has the sole task of replacing the blanks in the carton magazine, as an alternative to the semi-automatic format change (approx. 15 minutes), which requires some additional manual operations. Another upgrade is

the “intelligent” fully electronic divider. The new supply was appreciated by the Customer and definitely confirms the synergy between the two partners.

Moreover, in addition to the technological result in terms of solutions for the market, the Companies share their green attitude by endorsing sustainability in the Organic segment and in choosing packaging materials made with 100% recyclable consumables.

For more information pleas visit:

www.gampackgroup.com