The best choise for the honing’s future!

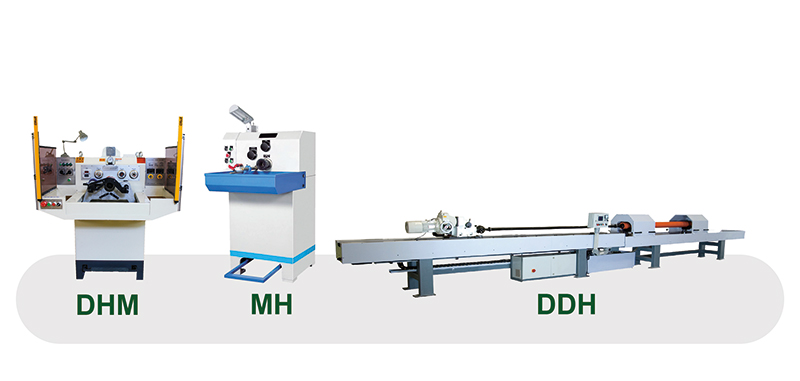

DAMEC SRL produces dynamic honing machines that have, as their main feature, their removal speed that are able to optimize every production phase without decreasing the quality of the workpieces.

Honing is a manufacturing process which gives to workpieces excellent precision and roughness characteristics.

Case, it could be made than the eventually aesthetic treatment.

Our application’s range is expanding in many fields; from general mechanics to manufacturing of hydraulic hoses and distributors, injectors, gears, hydraulic pumps, bushings, carbide, ceramic, glass and much more etc…..In the end it can be affirmed that in any field where are required incredibly low roughness, finish or surface treatment of cylinders, oleodynamics and after finishing processes.

Our honing machines, as their operating programme are unique and efficient, they could be personalized in relations to the specific request of the costumer.

Thanks to our highly and specialized technical staff, that is able to solve all kinds of problems and is always aimed at continuous research and technological evolution, our work is rewarded by the satisfaction and loyalty of our customers.

As well as our honing machines, Damec’s goods are delivered ready to be used: no set up or adjustment are needed.

Whether it’s a honing machine, automatic or manual, Damec’s products are suitable for almost honing machines of other brands; regardless of the length or hole’s diameter or that it’s a blind or through hole.

Our honing machines offer an ultraprecise manufacturing procedure chosen by high production workshops and manufacturers to create parts that work at the highest levels of speed and efficiency. No mechanical process can provide such precise levels of roundness, straightness and surface accuracy.

Why choose DAMEC SRL Price and times are reduced thanks to:

•Simple and quick piece reception equipment: it is not necessary to center the piece, as is the case with the grinding of internal diameters

•High chip removal with reduced cycle time: thanks to the action of more abrasive cutting edges

•Increased cutting power and reduced cycle time

•Constant linearity over the entire cutting length, especially in the presence of long holes: it is possible to assist in grinding to a curvature of the cylindrical shape (rainbow effect) •lower investment costs compared to other machining processes with similar precision requirements

•maximum surface quality: without altering the surface structure thanks to a high process repeatability

For more information please visit:

www.damec.eu