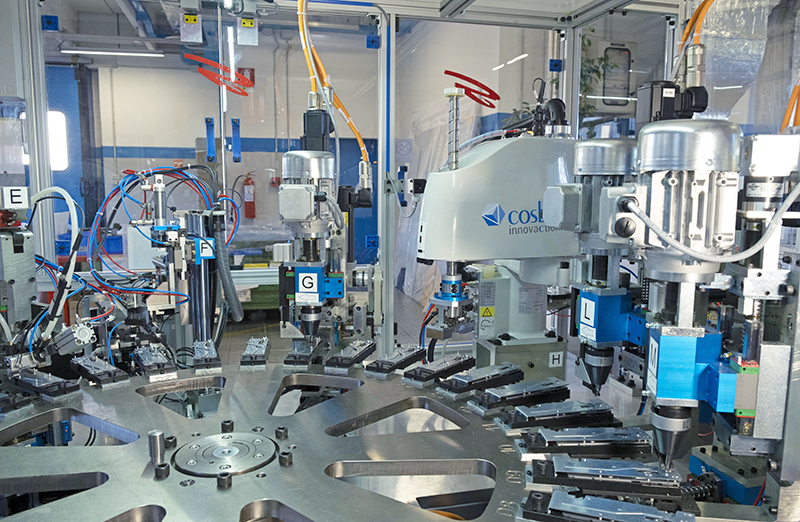

SPECIAL ASSEMBLY MACHINES

Always ready for new challenges:

Cosberg is Ready to Run, competitive at the Pit Stop and winner in I4.0 solutions

Cosberg’s mission is the designing and the building of special assembly systems, tailor-made machines capable of responding to the production and quality needs of our company’s customers.

For almost forty years Cosberg has been alongside European manufacturing companies and in various countries around the world for the industrialization of their products and the creation of solutions to optimize their assembly processes, where efficiency and flexibility are essential prerogatives, also suitable for assembling very small and critical pieces.

The experience gained and the propensity for continuous technological innovation allow us to have customers in sectors ranging from Automotive to Electromechanical, from furniture hardware to mechanisms and accessories for Household Appliances, up to jewelery and watchmaking.

In the development of its solutions, Cosberg wanted to strengthen those technical advantages that it has always guaranteed on its machines to reduce machine downtime, necessary, for example, for production changes or ordinary maintenance, ensuring high production levels and constant machine performance.

During the study and construction phase of our machines we use the most cutting-edge technologies, making them accessible to everyone and taking into account the suggestions collected over the years thanks to a fruitful collaboration with our customers, obtaining:

– Low-Maintenance. The parts subject to wear are positioned in a way to facilitate maintenance or replacement interventions. Furthermore, we work since longtime ago for a standardization of components and modules to simplify and make spare parts management less expensive.

– Objective and Productive Acceptance Test: The acceptance test is also feasible remotely with the support of specific devices and software. With this proven testing system, all the critical parameters of the machine (electrical, mechanical, etc.) are monitored in real time by sensors and software capable of providing objective data.

This allowing to overcome the travel limits and, at the same time, training of the staff and production of good parts.

– Installation and Ramp-Up: our machines are made up of a monobloc chassis and are not disassembled for the transport so, the installation and start-up phase is contained in a time of 3 days, with the possibility of remote assistance. The ramp-up is reachable in few hours.

To complete its offer, Cosberg has developed a “Cosberg4Machine” monitoring software capable of providing real-time data relating to production, alarms, performance, quality and availability of the single work unit or of the entire machine or extended to the entire assembly department or factory. A web-based Technology system, easy to use, with customizable dashboards and accessible from any device.

All this allows us to be able to satisfy the demands of the markets by providing concrete and effective solutions with intelligent and interconnected machines, able to communicate with factory systems (MES) allowing the exchange of data and information in order to control and produce according to the demand of the moment.

In other words, we can say that our machines have already taken the evolutionary roads towards the Intelligent Factory model.

For more information:

www.cosberg.com

sales-ci@cosberg.com