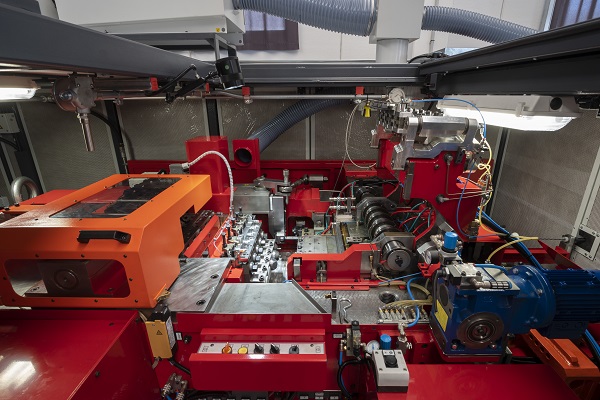

New header model CS 558 WS

Carlo Salvi SpA is a world-renowned designer and producer of heading machines for the production of screws, semi-tubular and fully tubular rivets, bolts, special fasteners and parts with very complex shapes starting from drawn wire in coils.

Machines can be divided in three main families, namely:

– single die double blow headers;

– 2-die 4-blow headers;

– progressive precision transfer headers.

This model of the 5-die progressive series can handle wire diameters from 4 to 12 mm. (10mm. with titanium or other special alloys)

The machine has been specially developed for the production of parts with extremely complex shapes. P.k.o.’s are available at each station and each p.k.o. can be adjusted independently from the others.

The machine can produce solid, semi-tubular and fully tubular parts.

Carlo Salvi has developed a new model which is called CS 558 WS which is an enhanced version of the model CS 558 machine. To handle of material like titanium and super alloys, which can not be formed with the cold heading system, the header can be equipped with a pre-heating system.

The customer can decide to install on the header model CS 558 WS the heating system with coil housed on the die holder, or the resin-bonded inductor positioned into the bedframe. In the event of special production needs, it is possible to evaluate also to install both kind of inductors.

The machine has been specially developed in order to minimize changeover times. Its technology and speed is such that it enables to run profitably not only large volumes but also small batches

Technical data of the header model CS 558 WS:

min and max wire diameter mm 4-12 mm (steel)

max shank length mm 80

max head diameter mm 20

max cutting tonnage daN 5500

max heading tonnage daN 80000

stroke of P.K.O.’s mm 30

Between the main standard features of this machine, we can list:

-Electronic adjustment of the wire engagement and of the wire stop

-P.K.O.’s on all punches

-trimming station on dies 4 and 5

-motorized lifting/lowering of transfer unit

-display on the touch screen of the k.o. pin position

-50 kW induction heating

Between the options of the CS 558 WS:

-Quick change kit

-bench with all centring jigs

-additional cutter unit

-additional complete punch block assembly

-additional complete die block assembly

-additional shaft complete with opening/closing finger cams

-additional 5 transfer finger units

– hoist for handling die block and punch block units

The header model CS 558 WS can be enriched further with some optional items as the Secomea device for remote assistance.

Through this highly performing solution it is possible to monitor, to manage and to service our machinery wherever they are, in compliance with the requirements of Industry 4.0.

No firewall configuration and no public IP are required, as the device points directly to the Site Manager server through Internet access via LAN, Wi-Fi or mobile phone (the latter optional), ensuring maximum security for the customer’s company network.

Carlo Salvi Spa Sales & Marketing team