Italian Gasket is a firmly established Company in the field of technical rubber items, with over 35 years of international experience through its three plants in Italy, Hungary and China.

Italian Gasket is a firmly established Company in the field of technical rubber items, with over 35 years of international experience through its three plants in Italy, Hungary and China.

QUALITY

Italian Gasket stands out for its attention to the quality of its products. The production process is structured in accordance with international quality models:

– ISO9001 (Quality System)

– IATF16949 (Automotive)

– OHSAS18001 (Security)

– ISO14001 (Environmental)

– ISO50001 (Energy Saving).

RESEARCH & DEVELOPMENT

Italian Gasket firmly believes in R&D.

To provide our customers with the most appropriate support to and build a relation of mutual trust, Italian Gasket has implemented a research and development system that:

– Develops material directly with polymer manufacturers.

– Supports customers through various tools:

o CO-DESIGN

o CAD-CAM

o Finite Element Analysis (FEA)

o CAE Simulations

MATERIALS

Italian Gasket works with most of the elastomers available on the market, in particular:

o AEM

o E(P)DM

o HNBR

o FKM

o VMQ

o LSR

o NBR

These materials can be supplied in accordance both with automotive regulations (PSA, DBL, VW, BMW) as well as according to other international standards (FDA, KTW, WRAS, EN549, UL, REACH, ROHS) PRODUCTS

PRODUCTS

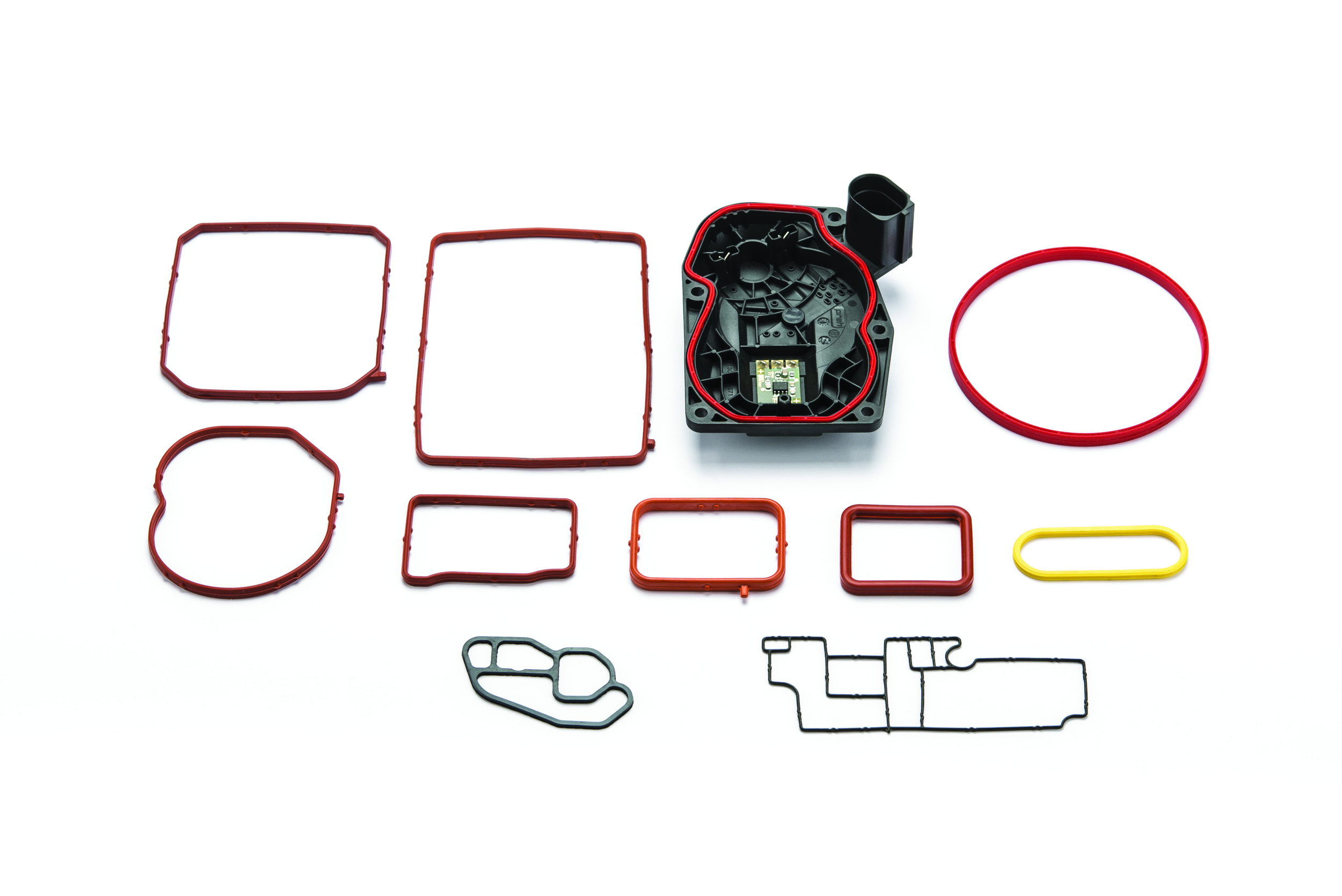

Italian Gasket produces rubber technical items through a process of injection or compression. Its deep knowledge of the automotive market allows the Company to maintain a high quality standard also valid for other markets, such as Oil & Gas, automation, naval, thermosanitary. Italian Gasket can also supply assembled items (rubber and metal or rubber and plastic), in order to provide our customers with a finished application ready to be assembled.

Our range of products include:

– Bellows

– Membranes

– Anti-vibrant

– Frames

– O-rings

– Connectors

– Suction Cups