GM International is an Italian based company engaged in designing, engineering and manufacturing a complete range of intrinsically safe and SIL certified devices that meet the stringent quality requirements, ensuring the highest production standards in intrinsically safe applications. The company was founded in 1993, but the core management experience remarkably exceeds over 40 years of qualified activity in intrinsic safety and industrial electronics. GM International designs intrinsically safe instruments and SIL certified devices in order to prevent accidents and understand, manage and reduce risks for people and environment. Our products have been successfully installed in plants all over the world and they interface all wiring between safe and hazardous areas and represent a fundamental, yet often underestimate layer of the instrumental package. GM International products are used in automation packages such as DCS, ESD, FGS, BMS, HIPPS, PLC and Scada, in several sectors like oil& gas, petrochemical, pharmaceutical, fertilizer, mining, marine and food & beverage industries. GM International is course promoter of the TÜV Rheinland Functional Safety Program for Safety Instrumented Systems (SIS) trainings. The course focuses on functional safety aspects for the process, oil & gas, and chemical industries according to IEC 61508 and IEC 61511. For more information on GM International visit: www.gminternational.com

Certified intrinsically safe products

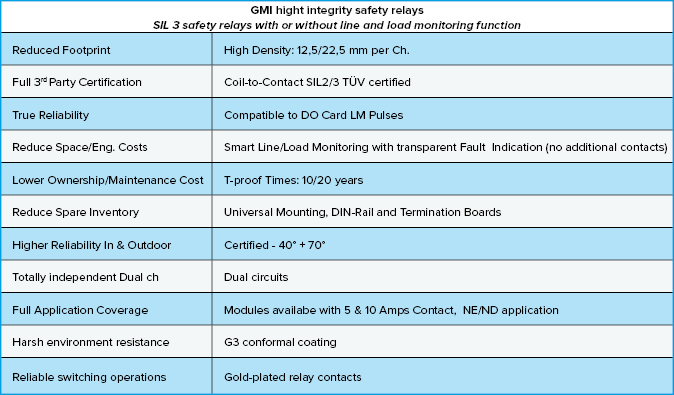

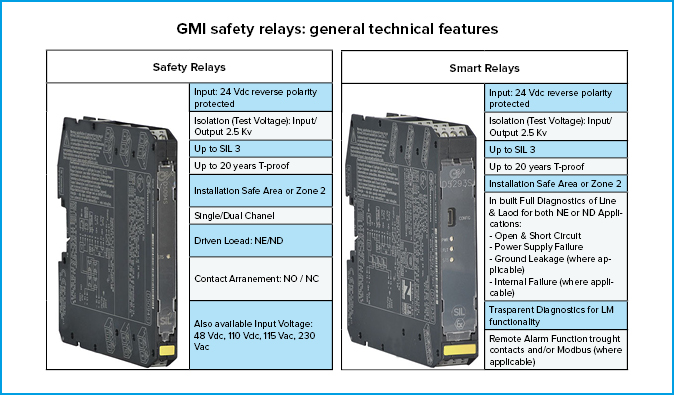

From the latest intrinsically safe interface, to safety relays for high integrity applications, to enhances power supply units with high availability, GM International products represent the most advanced solution for today’s critical applications; they provide energy limitation to protect from risks of explosion while providing the highest grade of availability to guarantee both continuous operation and effectiveness of safety layer. GM International products are certified up to SIL 3 and offer the highest levels of functional safety and availability for any application. GM International products have been granted I.S. certificates from the most credited Notified Bodies in the world. Certificates are available for ATEX (Europe), IECEx (International), UL/FM (USA and Canada), EAC-EX (Russia CTU and Ukraine), NEPSI (China), PESO (India), TIIS (Japan), INMETRO (Brazil). GM International offers a wide range of products that have been proved to comply with the most severe quality and safety requirements. IEC61508 and IEC61511 standards represent a milestone in the progress of industry in the achievement of highest levels of safety through the entire instrumented system lifecycle. For more information on GM International products visit: www.gminternational.com

A standard relay can’t be used in a Safety Instrumented Function

Risk reduction should be a priority for any business to protect the employees and prevent or mitigate a specific hazard and consequently, the risk of costly accidents or equipment replacement. Generally, if a risk can be reduced, then it should be. Safety Relays are devices that implement safety functions: in the event of a hazard, a safety relay will work to reduce the risk within an acceptable level.

When an error occurs, the safety relay will initiate a safe and reliable response. Each safety relay monitors a specific function. By connecting it to other safety relays, it is possible to achieve a total monitoring of a machine or plant. Safety relays are a simple and efficient way to meet existing safety standards, resulting in safe operations for the personnel and the equipment as well as a long service life.

Some of the functions that safety relays include:

- Stopping a movement in a controlled and safe manner

- Monitoring the position of movable guards

- Interrupting a closing movement during access

- Emergency off/stop

Safety relays are simple to operate and have a clear structure. The use of safety relays has become widespread due to their compact design, high reliability, and most importantly they meet all the required standards. Safety relays have become an integral component of any new plant or machine where safety functions are necessary. A standard relay can’t be used in a Safety Instrumented Function (SIF), for this reason, whenever it is necessary to use a relay complying with IEC 61508 and the relevant industry standard (for example 61511), we must refer to a safety relay.

SIF refers to equipment designed to prevent or mitigate the risks of a specific hazard. It detects the imminence of an incident, decides to take a specific action and acts to bring the process back to a safe state.

A SIL (Safety Integrity Level) certified relay (Safety Relay) has a known and guaranteed ability to perform a given Safety Function and reach a specific safe state on demand (i.e. open a relief valve or activate a Fire Extinguishing System). Typical cases of application of a SIL certified relays are represented by a controller that can’t meet the power requirement (V or A), or when multiple contacts are required, or the controller safety function must be inverted.

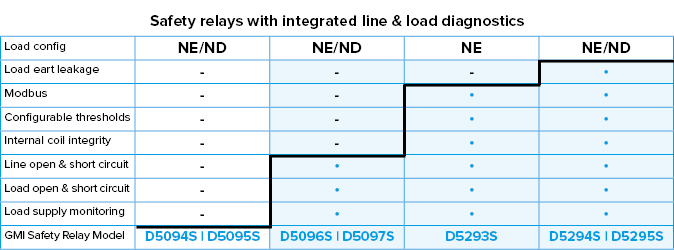

SIL (Safety Integrity Level) Certified Relays are used for critical loops where careful consideration should be given to Line and Load Monitoring.

In applications, such as F&G systems, line and load monitoring are fundamental, and Smart Relays become a valuable tool. Smart Relays are devices that implement the load and line diagnostics functions to the safety functions of a safety relay. Thanks to specific contact arrangement, GM International relay modules maintain higher level of safety while improving process availability (a single fault is not enough for a spurious trip of the load).

SIL certified relays are not used exclusively in Oil & Gas or Petrochemical industries, they are also a must in many other industries like railways, cars and lift, power distribution and anytime a failure of the relay can cause a serious accident.

In conclusion, you should never consider safety and availability mutually exclusive. Choosing the right SIS can ensure that your personnel and your plant are perfectly safe without you having to suffer any economic loss.

For more information visit: www.gminternational.com