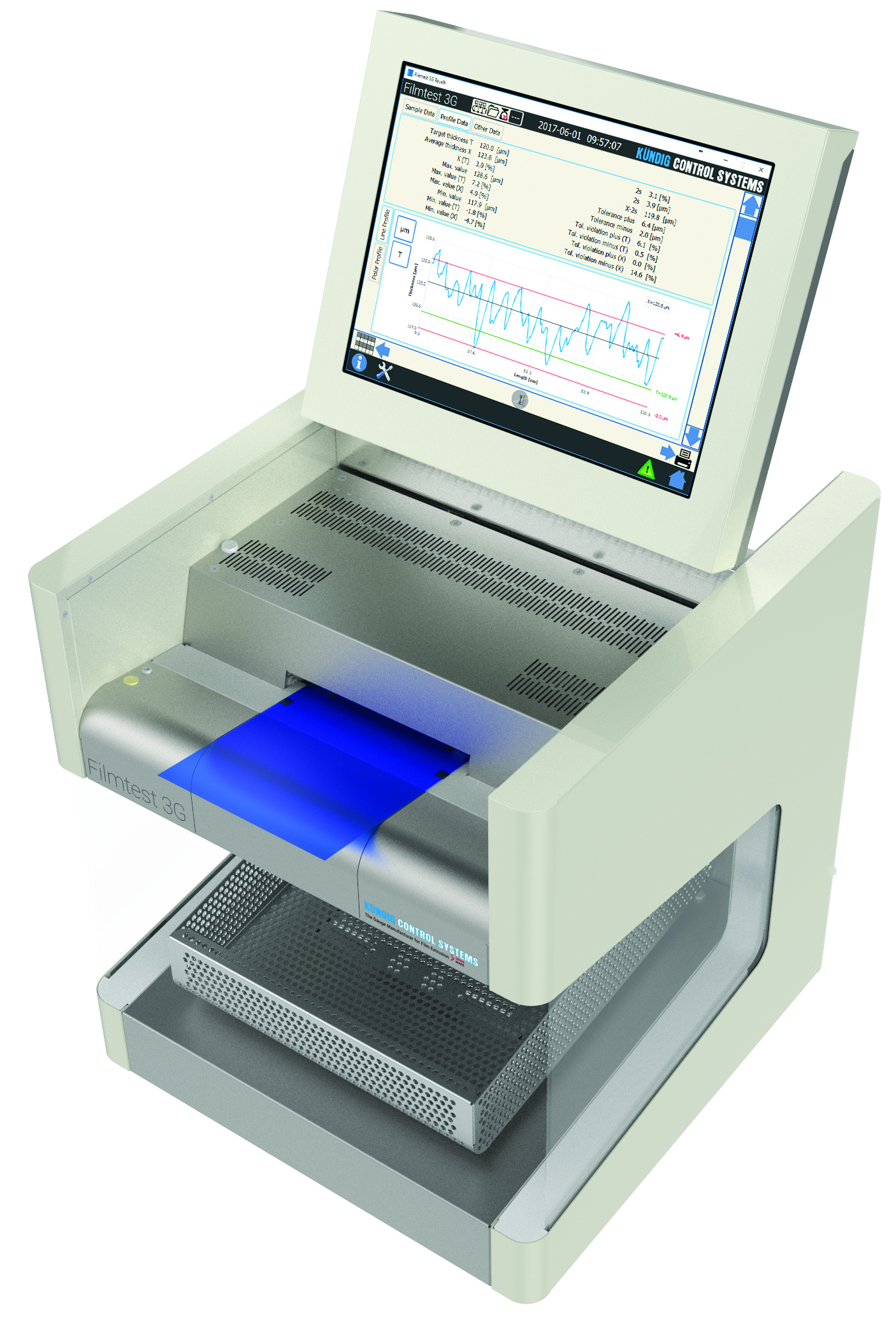

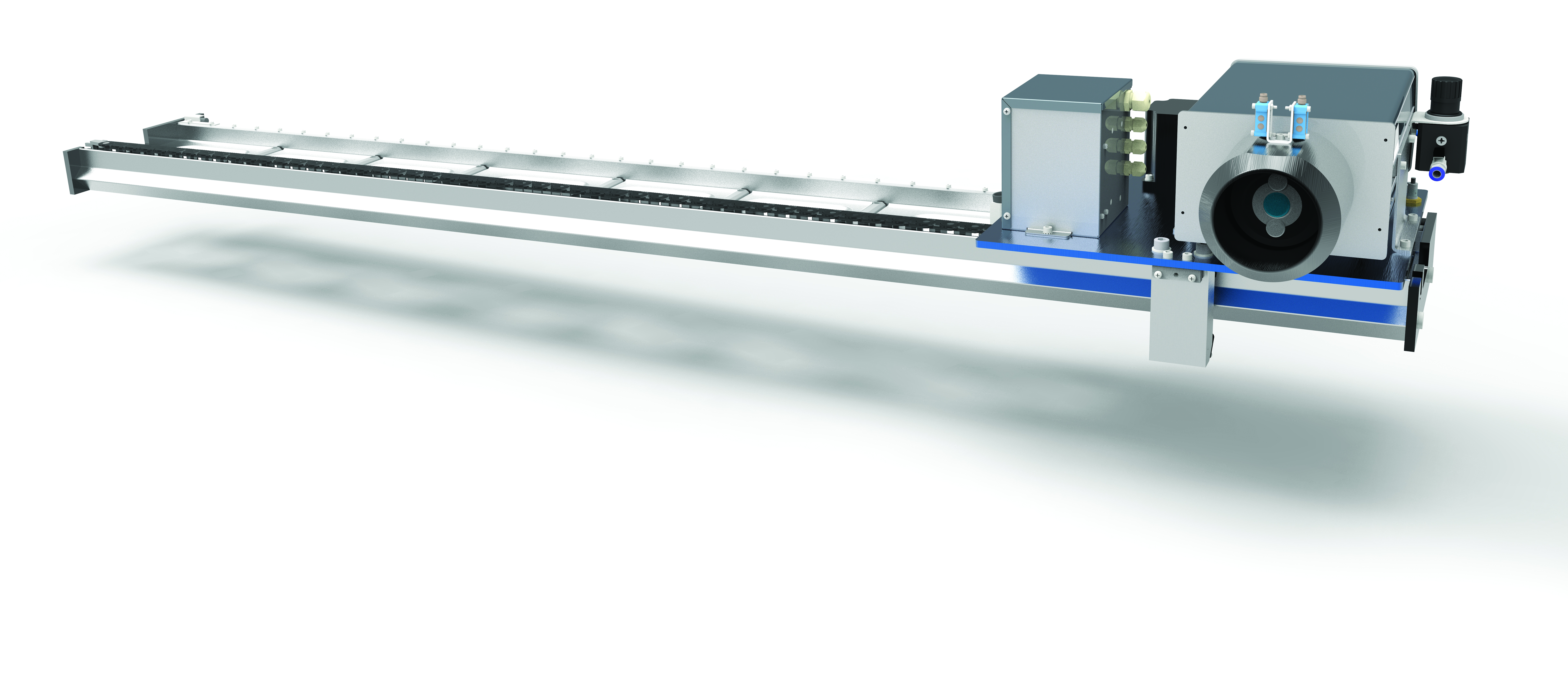

Measurement and control instrumentation made by Kündig Control Systems (KCS) – a member of Hch. Kündig & Cie. AG Group since 1972 – is used continuously around the world to guarantee best possible film quality. KCS is striving to maintain this target achievement despite stricter quality demands and annual increases in extrusion volumes. To do so, KCS is constantly improving measurement accuracy of existing sensors and is making use of newly available technologies to develop new sensor types and measuring methods.At the last K Fair, the company presented its new K-500 capacitive thickness sensor for online thickness measurement on blown film lines. The K-500 has an extremely low-wear and gap-free surface based on a patent-protected sintered ceramic cover through which the film is measured. Over the past three years, this type of sensor has become the standard gauge in the global marketplace for contact, high-precision thickness measurement.Since the beginning of 2018, KCS has been selling its third-generation version of the KNC-600 Linear Scanner. One of the uses of this travelling, non-contact, capacitive thickness gauge is for inline longitudinal stretching (inline MDO) on blown film lines.KCS will, of course, also be presenting its latest sensor development at this year’s K Fair. Until then, however, the company is only revealing the advertising slogan – “Lowering the Barriers.”This year, in keeping with tradition, an offline thickness gauge for process optimisation and quality control will again be on demonstration at the KCS booth. Visitors to the booth can bring their own film samples for measurement using the Filmtest 3G.

“Committed to film quality” also means that KCS offers its product users the best possible customer service. Since 2015, the internet platform GaugeCloud® has been online and is still being steadily expanded to this day. It gives customers access to literature, technical drawings, lists of available spare parts and much more information about their KCS products regardless of our business hours. Customers can, moreover, engage with three chat groups – Spares/Repair, Support and Retrofit – to communicate specifically with the relevant team of specialists. KCS technicians can use remote access to troubleshoot any problems that arise and can upload new software versions via the Internet . In the very latest products, this process even works for modules based on microprocessors.The KCS team is looking forward to welcoming long-standing and potential new customers to its booth C81 in Hall 10 at K’2019, to presenting its pioneering new products, and to showing the options for upgrading older KCS products.