A great number of workplace accidents still occur during maintenance. These accidents can cause severe human suffering, high insurance premiums and reduced production efficiency. Lockout/Tagout offers a practical way to control maintenance safety risks. Find out best practice in our guide book!

Brady’s best practice Lockout/Tagout programme includes:

- Define your maintenance risk control needs: we conduct or support on-site surveys to map the energy control points for every machine

- Choose the right locks & devices: you can select the right locks & devices for your needs from Brady’s complete offer

- Create best practice lockout procedures: we assist in creating, or we write best practice lockout procedures and offer the LINK360 software to easily approve, scale, edit, visualise and print lockout procedures

- Define maintenance risk control needs

Lockout/Tagout enables the temporary isolation of energy flows to machinery effictively rendering them inoperable while maintenance is ongoing. To isolate a machine, all its energy control points, such as handles, levers, valves and buttons, should be blocked in the off-position. Brady can conduct on-site Lockout/Tagout surveys to map all relevant energy control points for every single machine as a first step towards increased maintenance safety.

- Choose the right locks & devices

Once energy control points are mapped, selecting relevant lockout devices and padlocks becomes easy. The type and nu mber of lockout devices and padlocks needed will be determined by the energy control points present, by maintenance policies and by the on-site environment. Brady has lockout devices available to effectively lock out any machine, and padlocks in non-conductive, abrasion resistant, chemical resistant and many more versions to suit the needs of specific industries and contexts.

mber of lockout devices and padlocks needed will be determined by the energy control points present, by maintenance policies and by the on-site environment. Brady has lockout devices available to effectively lock out any machine, and padlocks in non-conductive, abrasion resistant, chemical resistant and many more versions to suit the needs of specific industries and contexts.

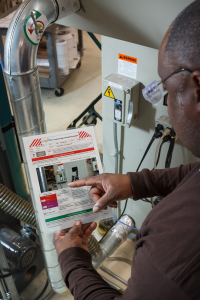

- Use best practice lockout procedures

When all energy control points are mapped and the right locks and devices are selected, clear step-by-step instructions need to be created so maintenance professionals can safely isolate machines before servicing them. Lockout procedures need to render machines inoperable, and should provide a tryout phase to check if any residual energy is left in the machine. To create safe lockout instructions, Brady sends experienced engineers to write best practice lockout procedures. With the LINK360 software, these procedures can easily be approved, scaled, visualised and printed by various stakeholders in multiple sites. Once approved, they can be visualised, printed and attached to the relevant machines using the LINK360 software.

Control maintenance safety risks with Brady’s complete Lockout Tagout offer, including software, services, devices and padlocks!

Download the Lockout/Tagout guide ‘Enable safer machine interventions’ for more information!